-

摘要:

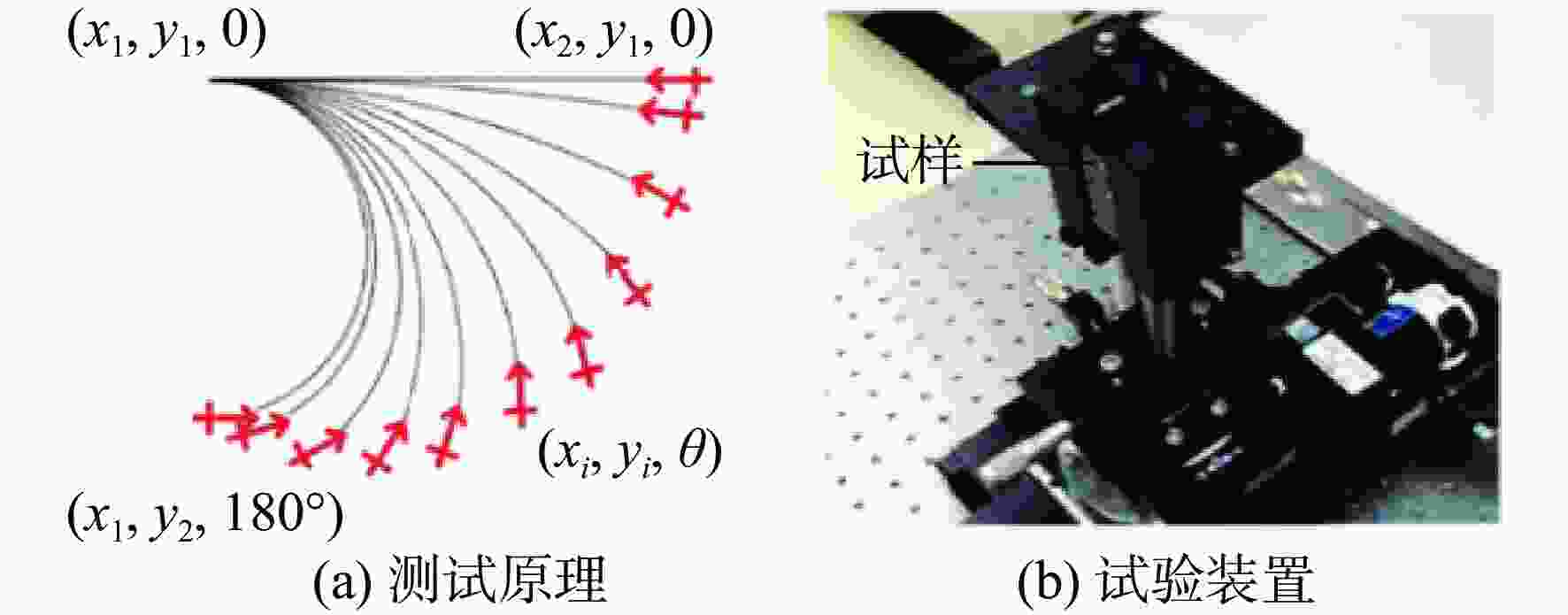

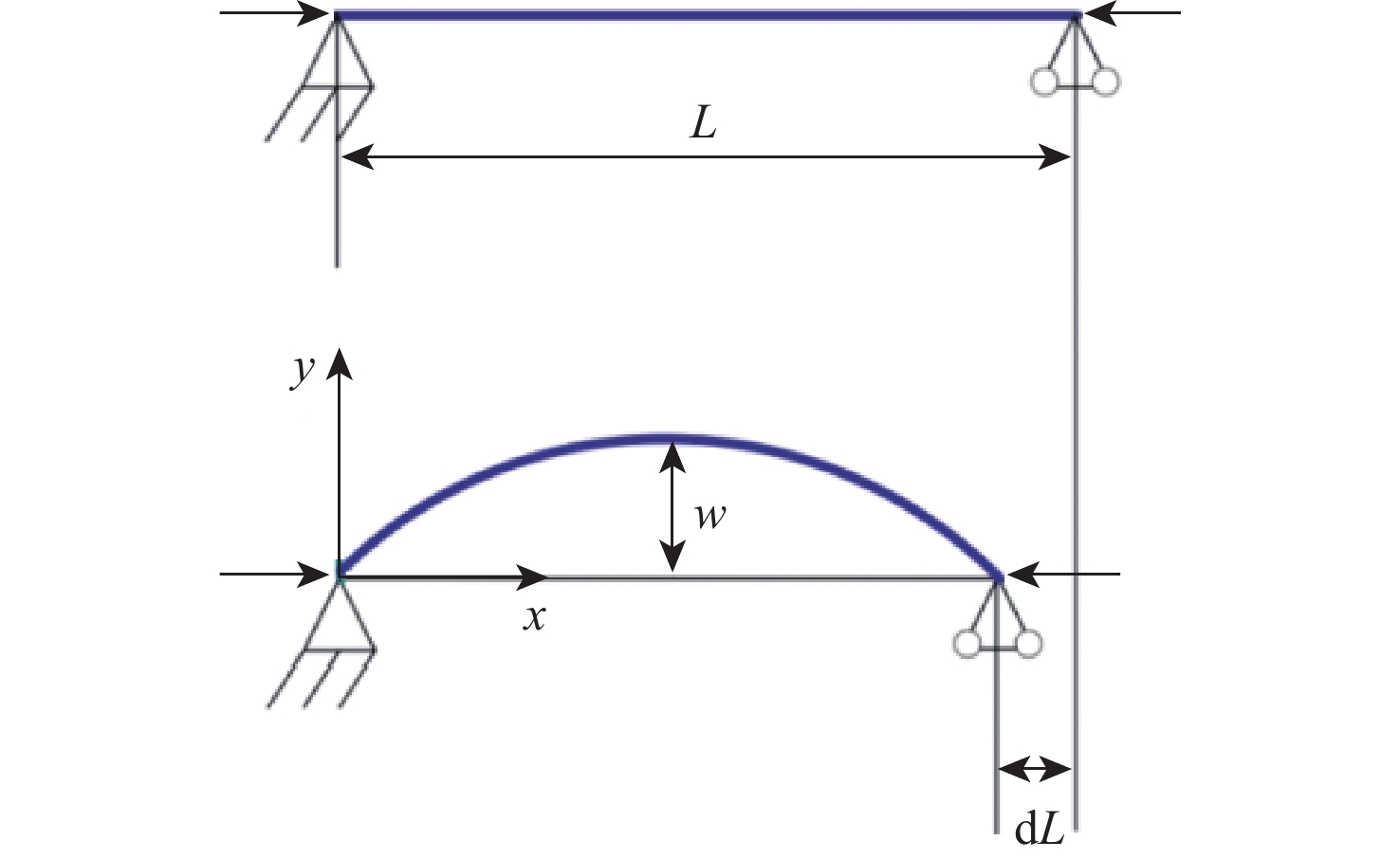

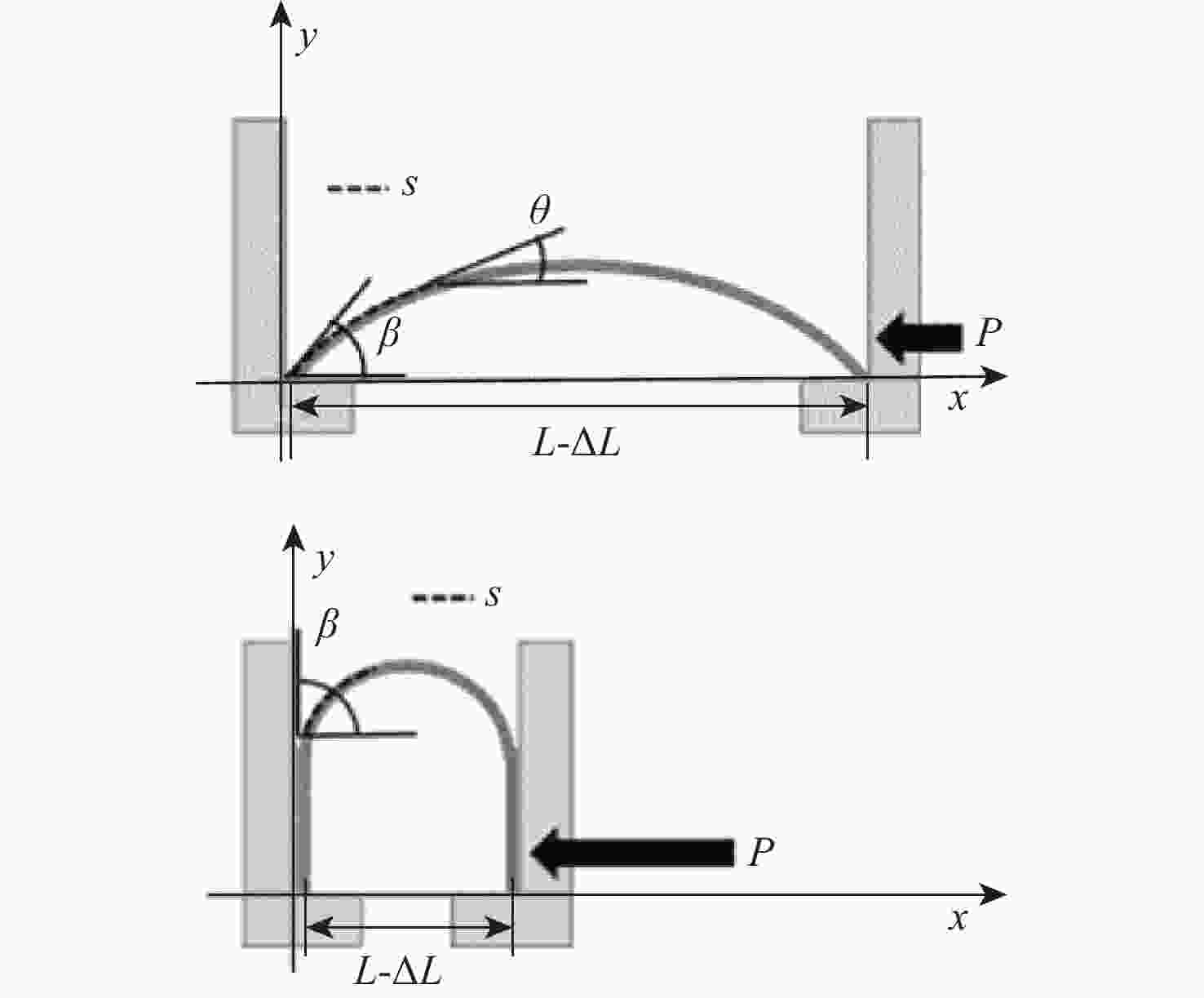

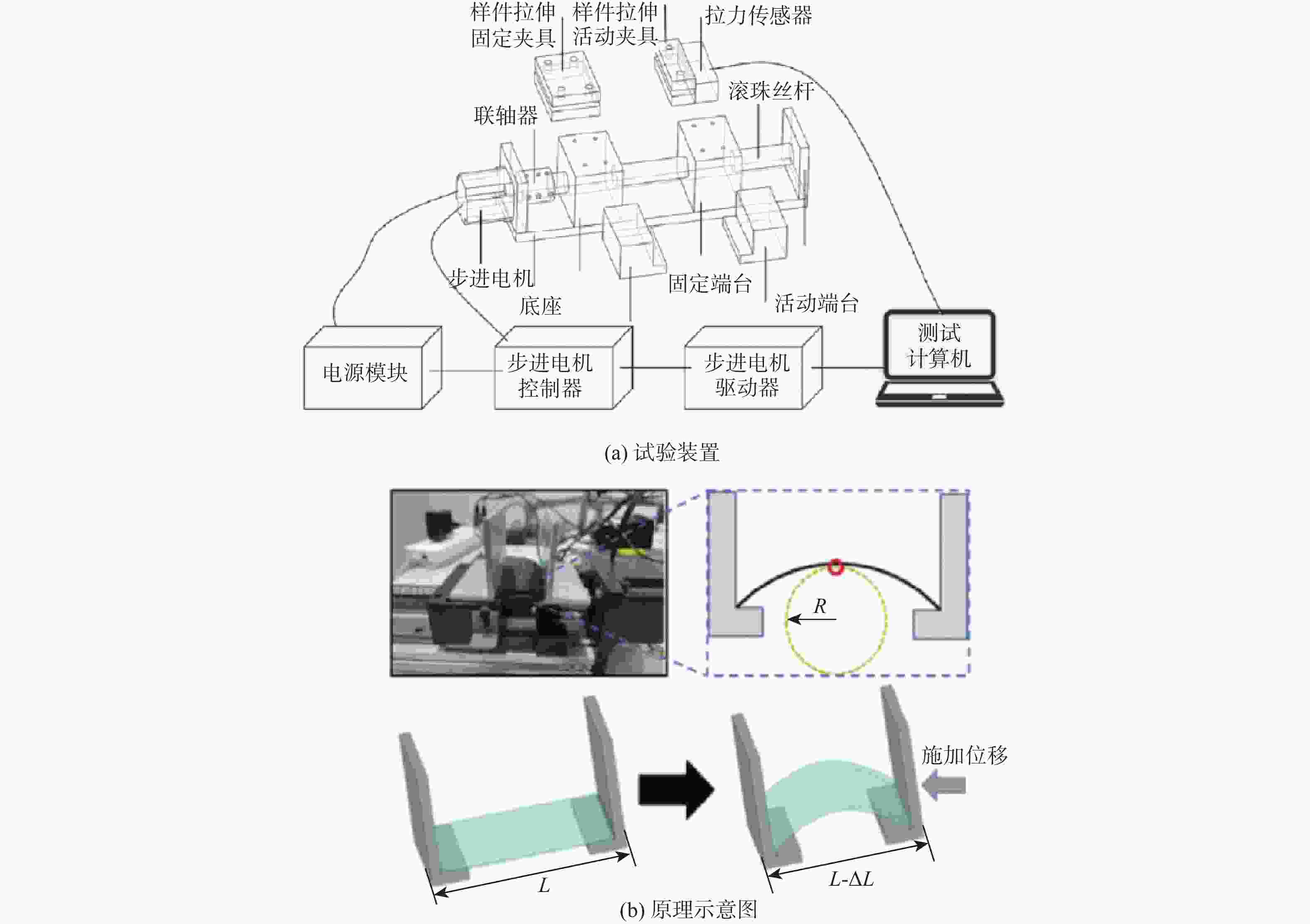

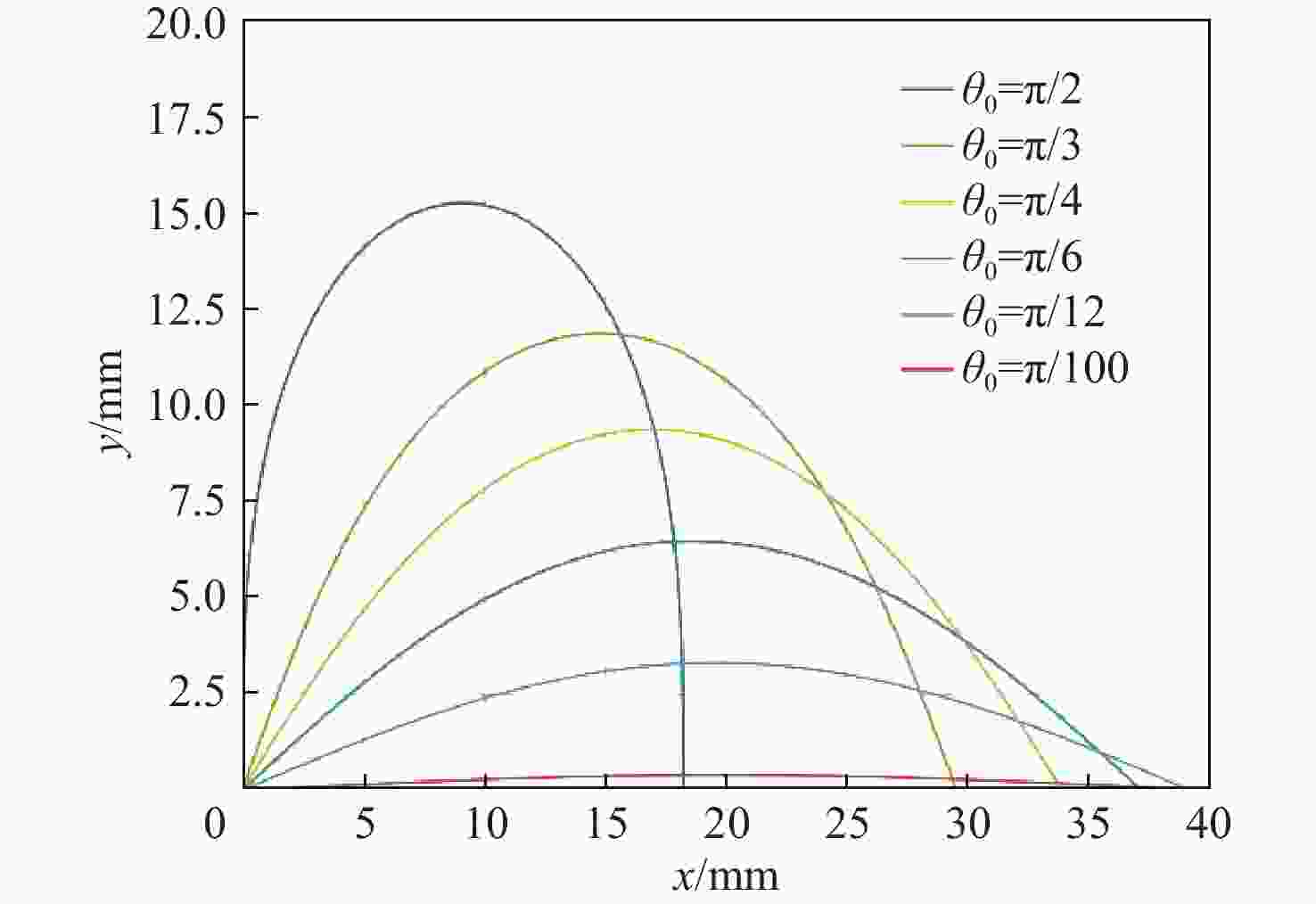

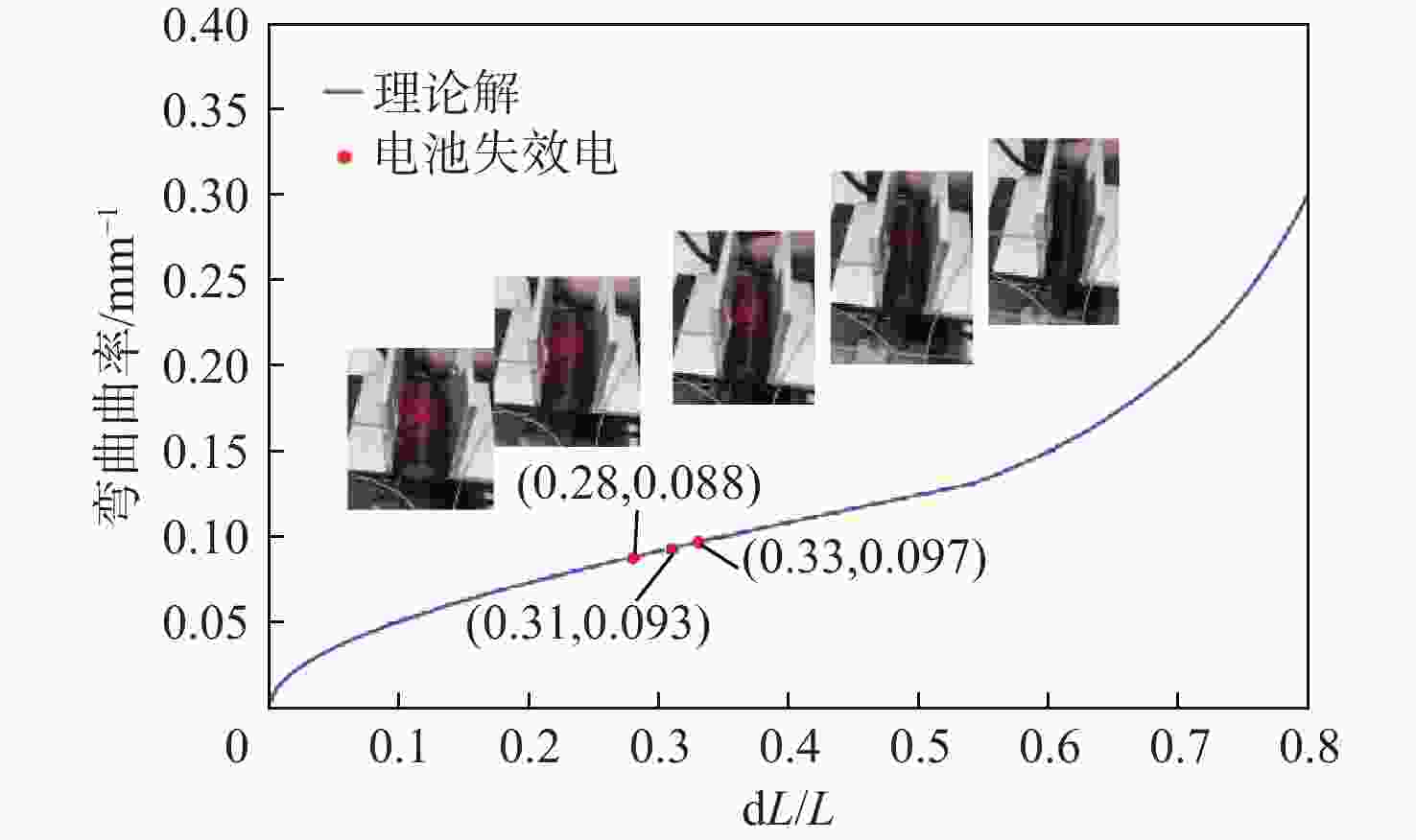

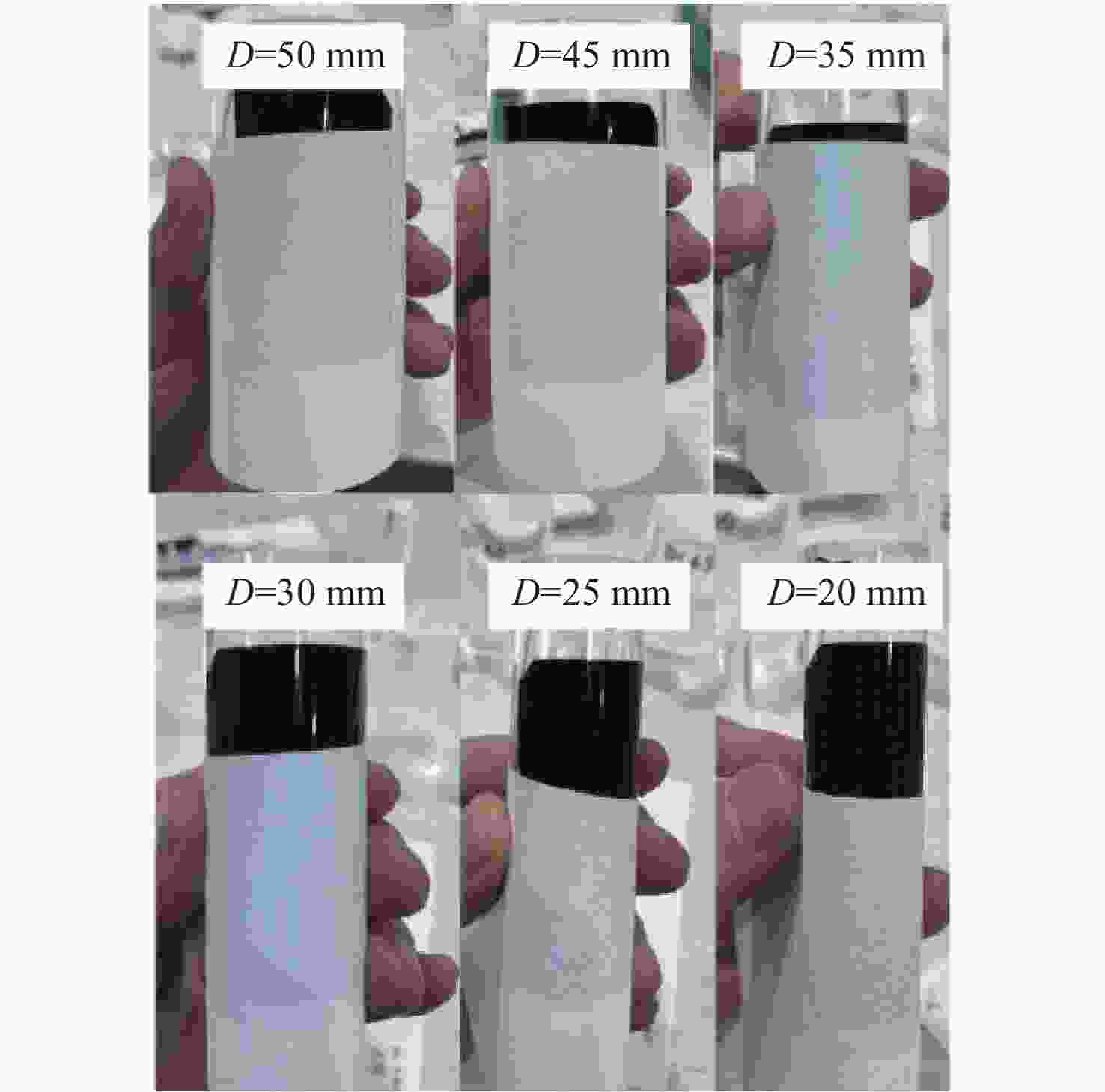

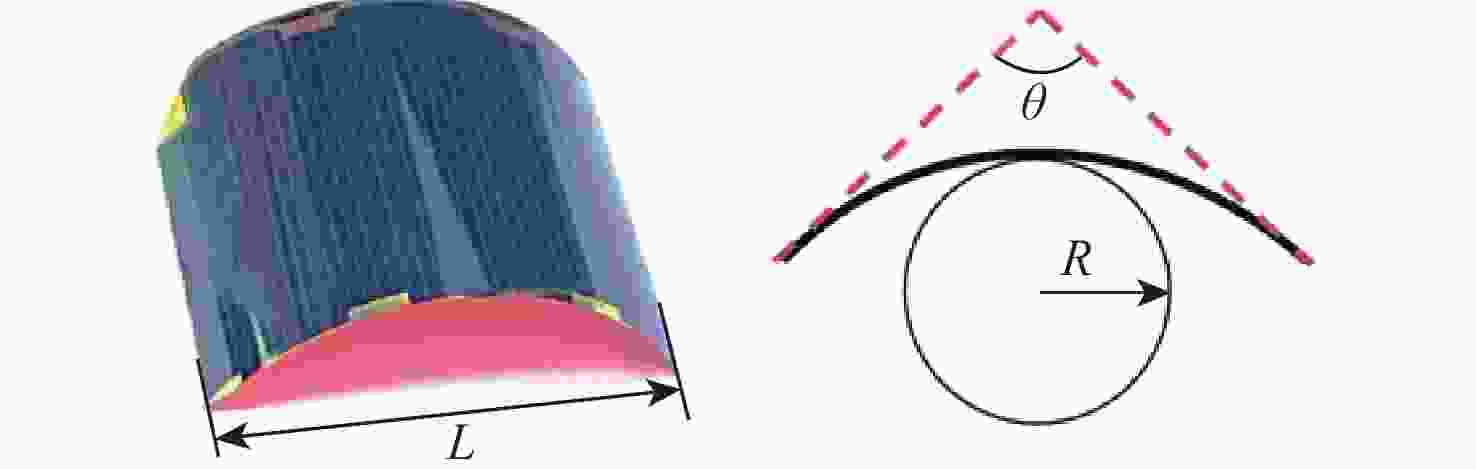

随着空间太阳电池阵从刚性半刚性电池阵向高收纳比、轻量化和低成本的柔性电池阵发展,柔性太阳电池逐渐成为未来空间能源系统的关键元件。然而,柔性太阳电池在弯曲状态下需保持光电转换效率和结构完整性,因此,对其极限弯曲半径的精确测量尤为重要。提出一种基于大挠度屈曲理论的柔性太阳电池弯曲半径测试方法,并搭建自动化测试平台。为验证该方法的准确性,将其结果与传统芯轴法进行对比。实验表明,利用大挠度屈曲法测得的极限弯曲半径与芯轴法的结果一致,证明了所提方法的准确性和可靠性,同时,该方法能够实现弯曲半径的连续可调测量,且自动化程度高。研究结果不仅为柔性太阳电池的结构设计提供了精确的力学参数,也为未来柔性电子器件的性能优化提供了参考依据。

Abstract:Flexible solar cells are becoming more widely acknowledged as essential elements for upcoming applications as space solar cell arrays move from rigid and semi-rigid structures to flexible designs with high packing ratios, less weight, and lower costs. The exact measurement of these cells’ essential bending radius is necessary because they must preserve both their structural integrity and photoelectric conversion efficiency under bending conditions. In response to this need, a new method based on large deflection buckling theory is proposed for testing the bending radius of flexible solar cells. Accurate and repeatable measurements are made possible by an automated testing instrument designed to support this method. To validate the accuracy of this method, its results were compared with those obtained using the traditional mandrel method. The accuracy and dependability of this method were confirmed by the trials, which revealed that the critical bending radius determined by the big deflection buckling method was quite compatible with that of the mandrel method. The findings of the study serve as a guide for maximizing the performance of upcoming flexible electronic devices in addition to providing exact mechanical parameters for the structural design of flexible solar cells.

-

-

[1] 于辉, 张伟, 崔新宇, 等. 空间太阳电池阵技术现状及发展趋势[J]. 电源技术, 2020, 44(10): 1552-1557. doi: 10.3969/j.issn.1002-087X.2020.10.038YU H, ZHANG W, CUI X Y, et al. Current status and development trends of space solar arrays[J]. Power Supply Technology, 2020, 44(10): 1552-1557(in Chinese). doi: 10.3969/j.issn.1002-087X.2020.10.038 [2] 杨淑利, 梁潇, 邵立民, 等. 空间柔性太阳电池阵发展现状及趋势[J]. 宇航学报, 2023, 44(12): 1810-1819. doi: 10.3873/j.issn.1000-1328.2023.12.003YANG S L, LIANG X, SHAO L M, et al. Development and trend of spacial flexible solar array[J]. Journal of Astronautics, 2023, 44(12): 1810-1819(in Chinese). doi: 10.3873/j.issn.1000-1328.2023.12.003 [3] 王凯, 王训春, 钱斌, 等. 高效太阳电池及其阵列技术的空间应用研究进展[J]. 硅酸盐学报, 2022, 50(5): 1436-1446.WANG K, WANG X C, QIAN B, et al. Research progress on the space application of high-efficiency solar cells and arrays[J]. Journal of the Chinese Ceramic Society, 2022, 50(5): 1436-1446(in Chinese). [4] LI J, AIERKEN A, LIU Y, et al. A brief review of high efficiency III-V solar cells for space application[J]. Frontiers in Physics, 2021, 8: 631925. doi: 10.3389/fphy.2020.631925 [5] 张伟, 兰志成, 吴致丞. 卫星卷绕式柔性太阳电池阵关键技术研究[J]. 电子技术应用, 2022, 48(6): 10-13.ZHANG W, LAN Z C, WU Z C. The key technical analysis of the roll-out solar array[J]. Application of Electronic Technique, 2022, 48(6): 10-13(in Chinese). [6] 金海雯, 于辉, 赵颖, 等. 半刚性太阳电池阵抗力学环境设计与分析[J]. 电源技术, 2012, 36(6): 813-815. doi: 10.3969/j.issn.1002-087X.2012.06.015JIN H W, YU H, ZHAO Y, et al. Against mechanical environmental design and analysis of semi-rigid solar array[J]. Chinese Journal of Power Sources, 2012, 36(6): 813-815(in Chinese). doi: 10.3969/j.issn.1002-087X.2012.06.015 [7] MAO L J, MENG Q H, AHMAD A, et al. Mechanical analyses and structural design requirements for flexible energy storage devices[J]. Advanced Energy Materials, 2017, 7(23): 1700535. doi: 10.1002/aenm.201700535 [8] YUAN Z S, YAO M J, ZHANG N N, et al. Mechanical analysis of flexible integrated energy storage devices under bending by the finite element method[J]. Science China Materials, 2021, 64(9): 2182-2192. doi: 10.1007/s40843-020-1613-4 [9] LAW D C, EDMONDSON K M, SIDDIQI N, et al. Lightweight, flexible, high-efficiency III-V multijunction cells[C]//Proceedings of the 4th World Conference on Photovoltaic Energy Conference. Piscataway: IEEE Press, 2006: 1879-1882. [10] FUKUDA K, SUN L L, DU B C, et al. A bending test protocol for characterizing the mechanical performance of flexible photovoltaics[J]. Nature Energy, 2024, 9: 1335-1343. doi: 10.1038/s41560-024-01651-2 [11] 李征泰. 柔性锂离子电池的失效分析及新型结构研究[D]. 成都: 电子科技大学, 2023, 10-20.LI Z T. Research on failure analysis and new structures of flexible lithium-ion batteries [D]. Chengdu: Electronic Science and Technology University of China, 2023: 10-20(in Chinese). [12] GREGO S, LEWIS J, VICK E, et al. Development and evaluation of bend-testing techniques for flexible-display applications[J]. Journal of the Society for Information Display, 2005, 13(7): 575. doi: 10.1889/1.2001215 [13] PARK S I, AHN J H, FENG X, et al. Theoretical and experimental studies of bending of inorganic electronic materials on plastic substrates[J]. Advanced Functional Materials, 2008, 18(18): 2673-2684. doi: 10.1002/adfm.200800306 [14] CHEN Z, COTTERELL B, WANG W, et al. A mechanical assessment of flexible optoelectronic devices[J]. Thin Solid Films, 2001, 394(1-2): 201-205. doi: 10.1016/S0040-6090(01)01138-5 [15] TAGUCHI R, AKAMATSU N, KUWAHARA K, et al. Nanoscale analysis of surface bending strain in film substrates for preventing fracture in flexible electronic devices[J]. Advanced Materials Interfaces, 2021, 8(5): 2001662. doi: 10.1002/admi.202001662 -

下载:

下载: