Prediction of aeroengine rotor unbalance considering multi-source errors in assembly process

-

摘要:

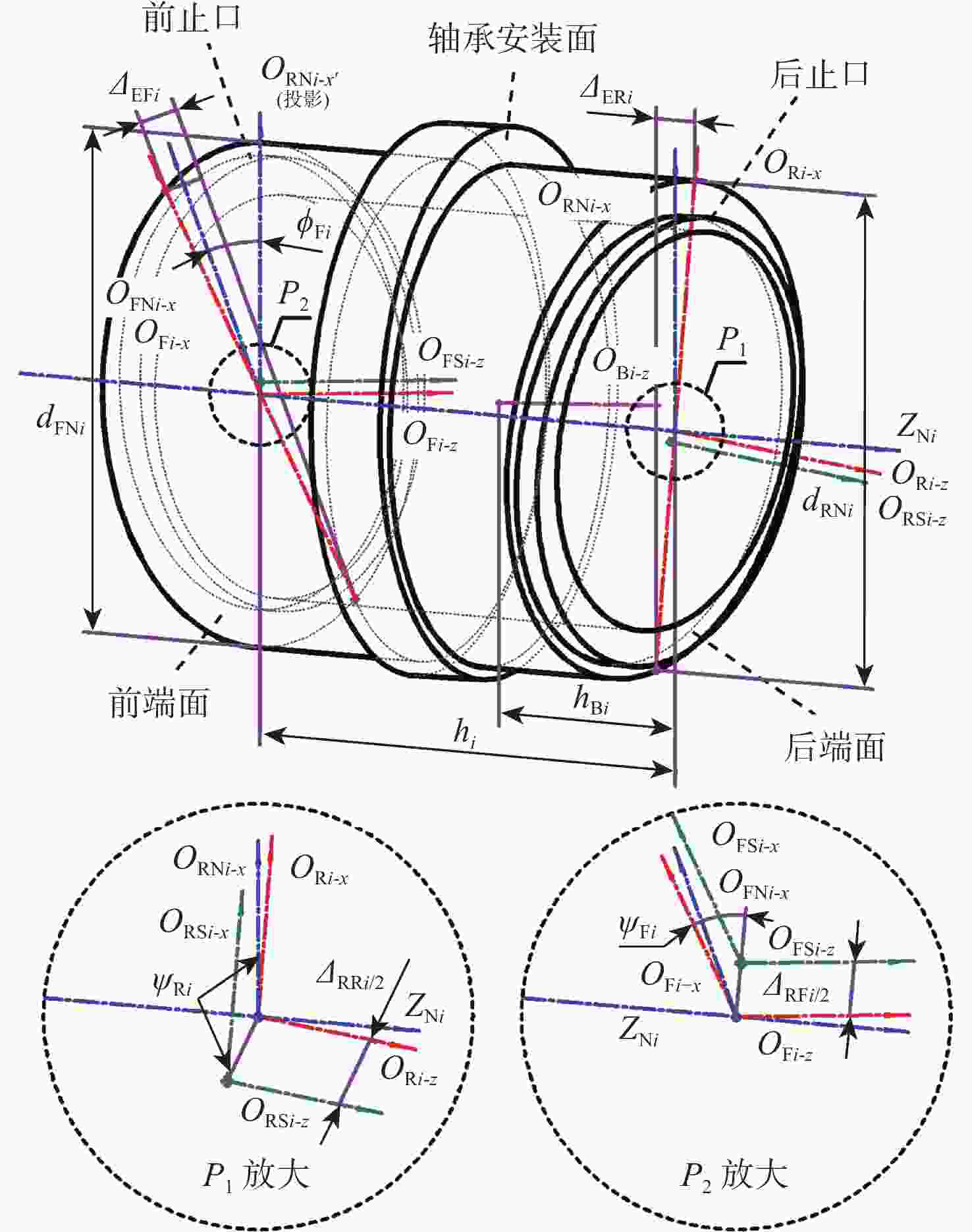

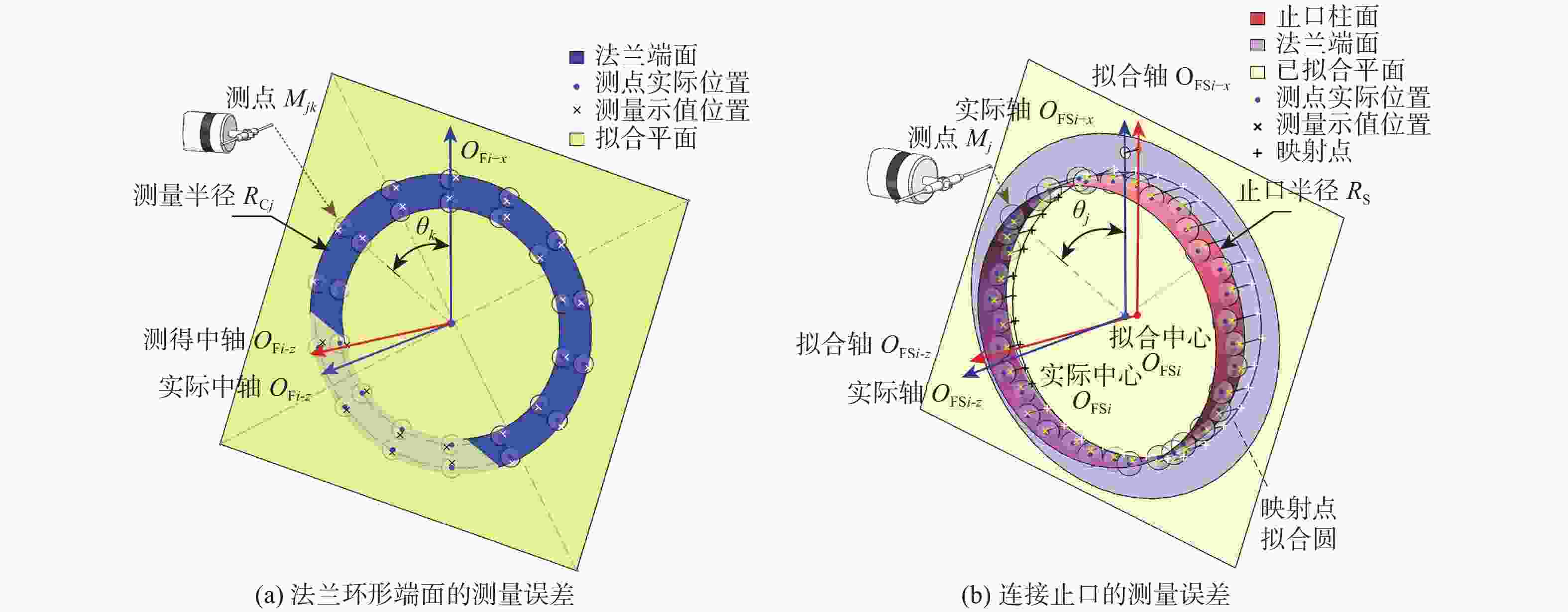

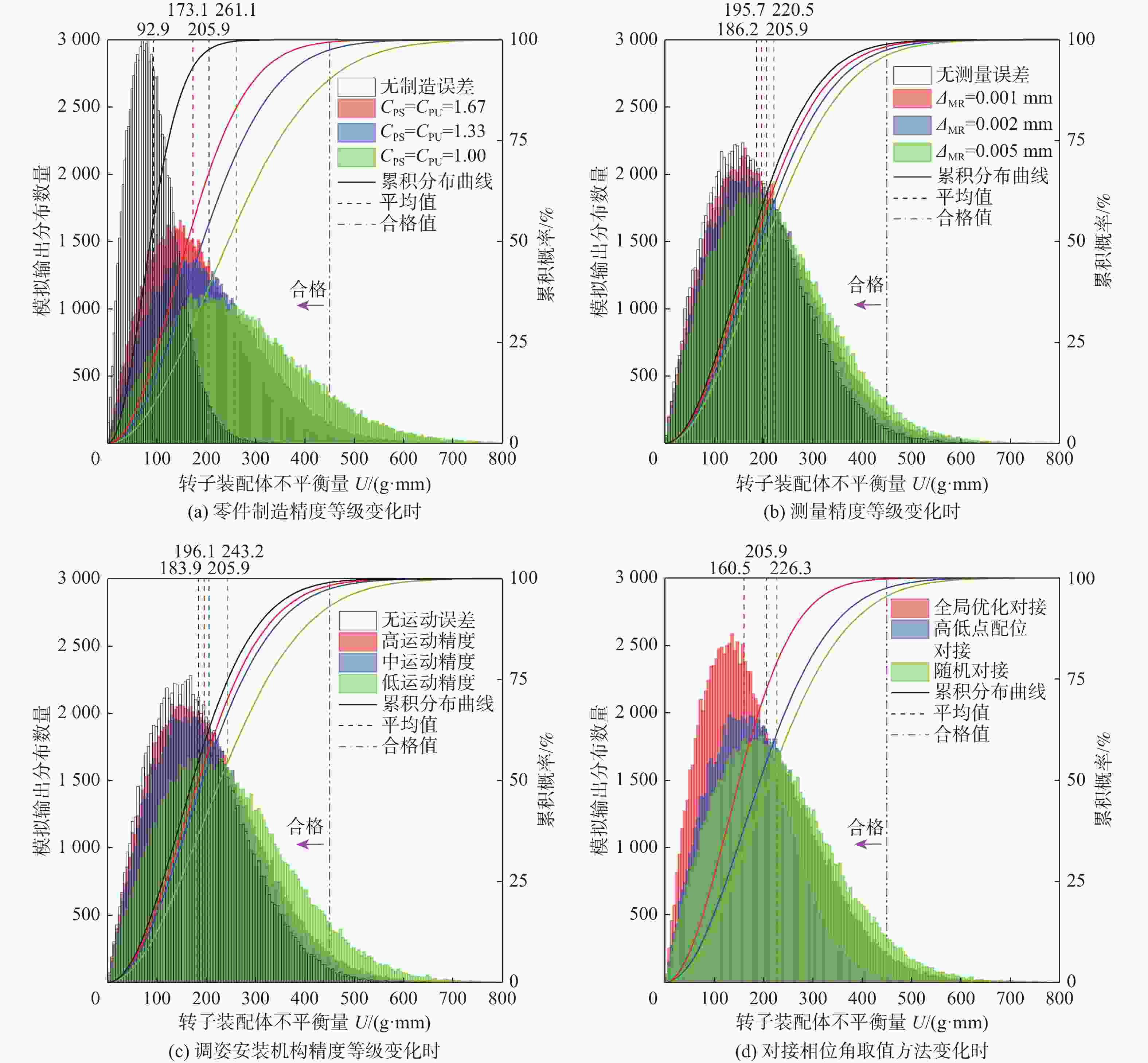

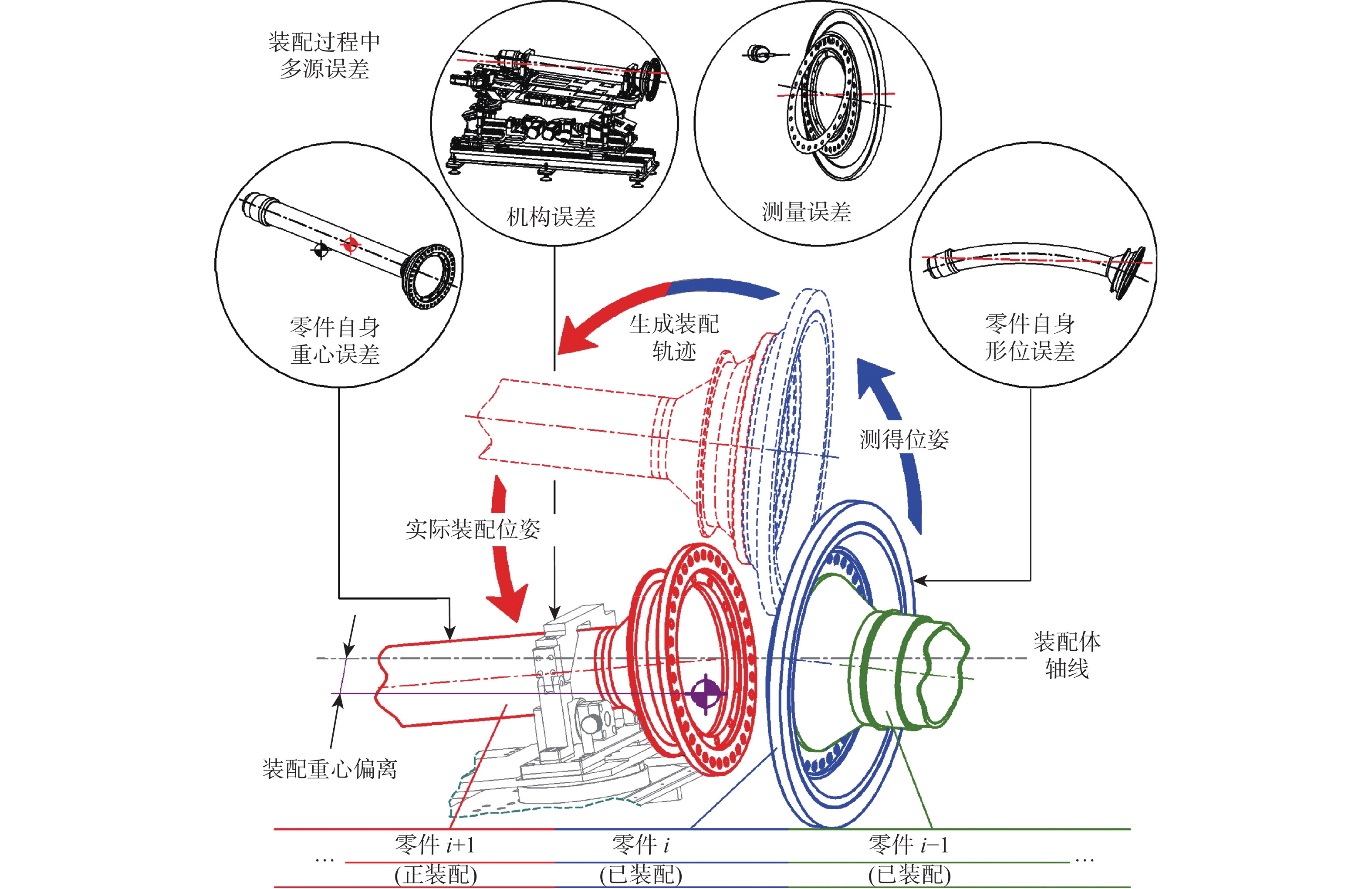

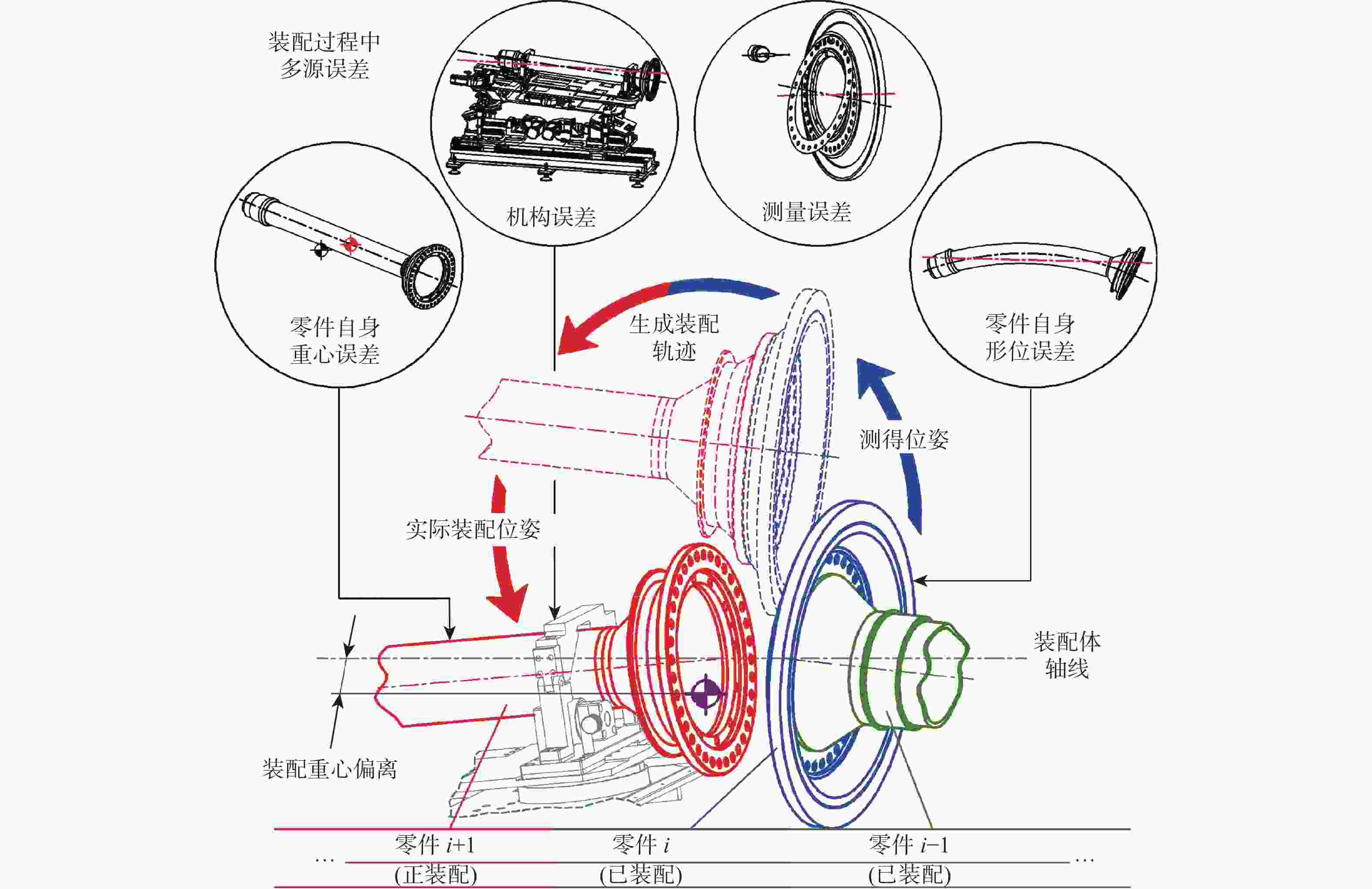

针对航发转子在复杂装配系统下产品不平衡量难预测问题,提出虑及多源误差的不平衡量数值模拟预测方法,旨在实现工件组精度及其装配系统精度的可靠溯源设计。阐明了转子装配过程中工艺参数、多源误差、相对位姿及不平衡量之间的传递原理,分别建立了典型转子零件制造误差、法兰止口位姿测量误差和多自由度安装机构运动误差的量化表征模型。基于所建模型设计了转子不平衡量蒙特卡罗模拟算法,实现不同装配条件下的不平衡量预测,以低压涡轮转子模拟件为实例,通过敏感度综合分析实现了其装配系统的精度优化反求,模拟获得不平衡量合格率达99.8%,提供了可靠的精度设计依据。进行装配验证实验,结果表明:不平衡量均值相对预测结果的偏离率均<10%,所提方法具有较高准确度。

Abstract:To address the difficulty in predicting the unbalance of aeroengine rotors assembled by complex assembly system, this paper proposed a numerical simulation method for unbalance considering multi-source errors, aiming to achieve the reliable traceability design of the accuracy of workpiece group and its assembly system. Firstly, the transmission principle among process parameters, multi-source errors, relative pose, and unbalance during the rotor assembly process was clarified. Quantitative characterization models were established for typical rotor part manufacturing errors, flange and spigot pose measurement errors, and multi-degree-of-freedom installation mechanism motion errors. Then, a Monte Carlo simulation algorithm for rotor unbalance was designed based on the above models. It realized unbalance prediction under different assembly conditions. For the analysis case of a low-pressure turbine rotor simulator, the accuracy of its assembly system was optimized inversely through comprehensive sensitivity analysis. The qualified rate of corresponding simulated unbalance reaches 99.8%. The proposed simulation method provides reliable accuracy design reference. Finally, assembly verification experiments were carried out. The results show that the deviation rates between the averages of the experimental unbalance and the predicted unbalance are all less than 10%. Thus, the proposed prediction method has high accuracy.

-

Key words:

- aeroengine /

- rotor /

- assembly /

- unbalance /

- Monte Carlo /

- accuracy design

-

表 1 转子零件形位误差输入

Table 1. Input of rotor part shape and position errors

形位公差类别 公差值/mm 误差值的分布 误差方向角

的分布后轴后端面全跳动 0.03 ΔER1服从

N+[0,(0.01/CPS)2]后轴前端面全跳动 0.03 ΔEF1服从

N+[0,(0.01/CPS)2]ϕF1服从

R(0,2π)后轴前端止口同心度 ϕ0.03 ΔRF1服从

N [0,(0.005/CPS)2]ψF1服从

R(0,π)5支点轴承安装面同轴度 ϕ0.02 ΔB1服从

N [0,(0.0033 /CPS)2]ψB1服从

R(0,2π)锥形盘后端面全跳动 0.04 ΔER2服从

N+[0,(0.0133 /CPS)2]锥形盘后端止口同心度 ϕ0.03 ΔRR2服从

N [0,(0.005/CPS)2]ψR2服从

R(0,π)锥形盘前端面全跳动 0.04 ΔEF2服从

N+[0,(0.0133 /CPS)2]ϕF2服从

R(0,2π)锥形盘前端止口同心度 ϕ0.03 ΔRF2服从

N [0,(0.005/CPS)2]ψF2服从

R(0,π)低压涡轮轴后端面全跳动 0.04 ΔER3服从

N+[0,(0.0133 /CPS)2]低压涡轮轴后端止口同心度 ϕ0.03 ΔRR3服从

N [0,(0.005/CPS)2]ψR3服从

R(0,π)套齿联轴器安装面同心度 ϕ0.02 ΔB3服从

N [0,(0.0033 /CPS)2]ψB3服从

R(0,2π)表 2 转子零件不平衡量输入

Table 2. Input of rotor part unbalance

转子零件 不平衡量设计上限/ (g·mm) 对应矩阵元素及其分布 后轴 100 U1服从 N+[0,(33.3/CPU)2] 锥形盘 250 U2服从 N+[0,(83.3/CPU)2] 低压涡轮轴 500 U3服从 N+[0,(166.7/CPU)2] 表 3 装配系统中各关联精度的敏感度系数

Table 3. Sensitivity coefficient of each related accuracy in assembly system

输入的精度

等级敏感度系数 零件形

位精度零件不平衡

量精度测量

精度调姿安装

机构精度对接

方式低→中 0.06 0.19 0.17 0.06 0.09 中→高 0.05 0.09 0.04 0.05 0.20 -

[1] 陈予恕, 张华彪. 航空发动机整机动力学研究进展与展望[J]. 航空学报, 2011, 32(8): 1371-1391.CHEN Y S, ZHANG H B. Review and prospect on the research of dynamics of complete aero-engine systems[J]. Acta Aeronautica et Astronautica Sinica, 2011, 32(8): 1371-1391(in Chinese). [2] 陈果, 李兴阳. 航空发动机整机振动中的不平衡-不对中-碰摩耦合故障研究[J]. 航空动力学报, 2009, 24(10): 2277-2284.CHEN G, LI X Y. Study on imbalance-misalignment-rubbing coupling faults in aero-engine vibration[J]. Journal of Aerospace Power, 2009, 24(10): 2277-2284(in Chinese). [3] EWINS D J. Control of vibration and resonance in aero engines and rotating machinery-an overview[J]. International Journal of Pressure Vessels and Piping, 2010, 87(9): 504-510. doi: 10.1016/j.ijpvp.2010.07.001 [4] 陈立芳, 王维民, 高金吉. 航空发动机自动平衡技术发展综述[J]. 航空动力学报, 2019, 34(7): 1530-1541.CHEN L F, WANG W M, GAO J J. Summary on the development of auto-balancing technology of aero-engine[J]. Journal of Aerospace Power, 2019, 34(7): 1530-1541(in Chinese). [5] 张渝, 李琳, 陈津, 等. 航空发动机重要装配工艺分析及研发展望[J]. 航空制造技术, 2019, 62(15): 14-21.ZHANG Y, LI L, CHEN J, et al. Research current status and prospect on aero-engine assembly process technology[J]. Aeronautical Manufacturing Technology, 2019, 62(15): 14-21(in Chinese). [6] 石宏. 航空发动机装配工艺技术[M]. 北京: 北京亚洲成人在线一二三四五六区出版社, 2015.SHI H. Aeroengine assembly technology[M]. Beijing: Beijing University of Aeronautics & Astronautics Press, 2015(in Chinese). [7] SUN C Z, LIU Z W, LIU Y M, et al. An adjustment method of geometry and mass centers for precision rotors assembly[J]. IEEE Access, 2019, 7: 169992-170002. doi: 10.1109/ACCESS.2019.2955124 [8] SUN Q C, ZHAO B B, LIU X, et al. Assembling deviation estimation based on the real mating status of assembly[J]. Computer-Aided Design, 2019, 115: 244-255. doi: 10.1016/j.cad.2019.06.001 [9] YU L, ZHANG Y L, BI Q Z, et al. Research on surface normal measurement and adjustment in aircraft assembly[J]. Precision Engineering, 2017, 50: 482-493. doi: 10.1016/j.precisioneng.2017.07.004 [10] ZHANG M W, LIU Y M, SUN C Z, et al. Precision measurement and evaluation of flatness error for the aero-engine rotor connection surface based on convex hull theory and an improved PSO algorithm[J]. Measurement Science and Technology, 2020, 31(8): 085006. doi: 10.1088/1361-6501/ab8170 [11] 何晓煦, 田威, 曾远帆, 等. 面向飞机装配的机器人定位误差和残差补偿[J]. 航空学报, 2017, 38(4): 420538.HE X X, TIAN W, ZENG Y F, et al. Robot positioning error and residual error compensation for aircraft assembly[J]. Acta Aeronautica et Astronautica Sinica, 2017, 38(4): 420538(in Chinese). [12] LI Z H, TIAN W, WANG M, et al. Positioning error compensation of a flexible track hybrid robot for aircraft assembly based on response surface methodology and experimental study[J]. The International Journal of Advanced Manufacturing Technology, 2022, 119(1): 1313-1330. [13] ZHU Y G, HUANG X, FANG W, et al. Trajectory planning algorithm based on quaternion for 6-DOF aircraft wing automatic position and pose adjustment method[J]. Chinese Journal of Aeronautics, 2010, 23(6): 707-714. doi: 10.1016/S1000-9361(09)60273-9 [14] WHITNEY D E, GILBERT O L, JASTRZEBSKI M. Representation of geometric variations using matrix transforms for statistical tolerance analysis in assemblies[J]. Research in Engineering Design, 1994, 6(4): 191-210. doi: 10.1007/BF01608399 [15] DING S Y, HE Y H, ZHENG X H. A probabilistic approach for three-dimensional variation analysis in aero-engine rotors assembly[J]. International Journal of Aeronautical and Space Sciences, 2021, 22(5): 1092-1105. doi: 10.1007/s42405-021-00384-w [16] ZHOU Z L, LIU W, WU Q, et al. A combined measurement method for large-size aerospace components[J]. Sensors, 2020, 20(17): 4843. doi: 10.3390/s20174843 [17] 孙汕民, 孙传智, 冯硕, 等. 1种高精度大型阶梯轴圆柱轮廓测量模型[J]. 航空发动机, 2020, 46(2): 61-65.SUN S M, SUN C Z, FENG S, et al. One kind of high accuracy measurement model of large stepped shaft cylinder profile[J]. Aeroengine, 2020, 46(2): 61-65(in Chinese). [18] YANG J X, DING H. A new position independent geometric errors identification model of five-axis serial machine tools based on differential motion matrices[J]. International Journal of Machine Tools and Manufacture, 2016, 104: 68-77. doi: 10.1016/j.ijmachtools.2016.02.001 [19] ZHOU W Y, CHEN W Y, LIU H D, et al. A new forward kinematic algorithm for a general Stewart platform[J]. Mechanism and Machine Theory, 2015, 87: 177-190. doi: 10.1016/j.mechmachtheory.2015.01.002 [20] HUSSAIN T, MCWILLIAM S, POPOV A A, et al. Geometric error reduction in the assembly of axi-symmetric rigid components: a two-dimensional case study[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, 226(7): 1259-1274. doi: 10.1177/0954405412443471 [21] MEMON M, HUSSAIN T, MEMON Z A. Minimizing assembly errors by selecting optimum assembly sequence in the assembly of a rigid circular structure[J]. Mehran University Research Journal of Engineering and Technology. 2012, 31(4): 743-754. [22] BOLOTOV M A, PECHENIN V A, YU PECHENINA E, et al. Digital model to optimize the rotor assembly for aircraft engine compressor models[J]. Journal of Physics: Conference Series, 2021, 1745(1): 012033. doi: 10.1088/1742-6596/1745/1/012033 [23] QURESHI A J, DANTAN J Y, SABRI V, et al. A statistical tolerance analysis approach for over-constrained mechanism based on optimization and Monte Carlo simulation[J]. Computer-Aided Design, 2012, 44(2): 132-142. doi: 10.1016/j.cad.2011.10.004 [24] LEE N K S, YU G, JONEJA A, et al. The modeling and analysis of a butting assembly in the presence of workpiece surface roughness and part dimensional error[J]. The International Journal of Advanced Manufacturing Technology, 2006, 31(5): 528-538. [25] 胡明. 面向质量特性优化的航空发动机转子堆叠装配方法[D]. 哈尔滨: 哈尔滨工业大学, 2019.HU M. Stacked assembly method of aero-engine rotor oriented to optimization of quality characteristics[D]. Harbin: Harbin Institute of Technology, 2019(in Chinese). -

下载:

下载: