Review of low-temperature electrolyte of lithium-ion batteries for near space vehicle

-

摘要:

临近空间的低温环境对临近飞行器的电源系统提出了更高的要求。空间用锂离子电池(LIBs)作为空间电源系统的主要组成部分,在极端环境中的正常运行仍然面临着极高的技术壁垒。电解液,包括电解液本体相及固态电解质界面(SEI)膜,对锂离子电池在低温下的稳定运行十分关键。因此,开发先进的低温电解液对于锂离子电池在极端寒冷环境中稳定运行极其重要。从锂离子电池电解液角度出发,针对限制锂离子电池低温性能差的原因,综述了改善锂离子电池低温电解液的相关策略,对面向临近空间飞行器的锂离子电池低温电解液设计现状进行了分析。

Abstract:Higher demands have been placed on the power system of near-space missions due to the low-temperature environment. Lithium-ion batteries (LIBs), the primary power source for space systems, have significant technical obstacles to normal operation in harsh environments due to their rapid capacity deterioration and eventual battery failure at below-freezing temperatures. E For LIBs to function at low temperatures, electrolyte—including bulk electrolyte and solid electrolyte interface (SEI) film—is essential. Therefore, the development of advanced electrolyte for low-temperature conditions is important for the operation of LIBs in extremely cold environments. The design status of the low-temperature electrolyte of LIBs for near-space vehicles was evaluated, along with a summary of pertinent strategies to improve the LIBs of electrolyte for low-temperature conditions, with the goal of identifying the factors limiting the low-temperature performance of LIBs. This work provides a feasible strategy for the development of Energy storage equipment in near-space vehicles.

-

-

[1] 张海林, 周林, 马骁, 等. 临近空间飞行器发展现状及军事应用研究[J]. 飞航导弹, 2014(7): 3-7.ZHANG H L, ZHOU L, MA X, et al. Research on development status and military application of near space vehicles[J]. Aerodynamic Missile Journal, 2014(7): 3-7(in Chinese). [2] 黄宛宁, 张晓军, 李智斌, 等. 临近空间科学技术的发展现状及应用前景[J]. 科技导报, 2019, 37(21): 46-62.HUANG W N, ZHANG X J, LI Z B, et al. Development status and application prospect of near space science and technology[J]. Science & Technology Review, 2019, 37(21): 46-62(in Chinese). [3] TU Y G, WU J, XU G N, et al. Perovskite solar cells for space applications: progress and challenges[J]. Advanced Materials, 2021, 33(21): 2006545. doi: 10.1002/adma.202006545 [4] 谢赞, 周灿灿, 赵振涛, 等. 宽速域飞行器发展及研究现状综述[J]. 空天技术, 2022(4): 28-39.XIE Z, ZHOU C C, ZHAO Z T, et al. Overview of development and research status of wide speed range aircraft[J]. Aerospace Technology, 2022(4): 28-39(in Chinese). [5] ZHU G L, WEN K C, LV W Q, et al. Materials insights into low-temperature performances of lithium-ion batteries[J]. Journal of Power Sources, 2015, 300: 29-40. doi: 10.1016/j.jpowsour.2015.09.056 [6] CAI W L, YAO Y X, ZHU G L, et al. A review on energy chemistry of fast-charging anodes[J]. Chemical Society Reviews, 2020, 49(12): 3806-3833. doi: 10.1039/C9CS00728H [7] HOU J B, YANG M, WANG D Y, et al. Fundamentals and challenges of lithium ion batteries at temperatures between −40 and 60 ℃[J]. Advanced Energy Materials, 2020, 10(18): 1904152. doi: 10.1002/aenm.201904152 [8] ZHANG N, DENG T, ZHANG S Q, et al. Critical review on low-temperature Li-ion/metal batteries[J]. Advanced Materials, 2022, 34(15): 2107899. doi: 10.1002/adma.202107899 [9] SMART M C, RATNAKUMAR B V, EWELL R C, et al. The use of lithium-ion batteries for JPL’s Mars missions[J]. Electrochimica Acta, 2018, 268: 27-40. doi: 10.1016/j.electacta.2018.02.020 [10] WINTER M, BARNETT B, XU K. Before Li ion batteries[J]. Chemical Reviews, 2018, 118(23): 11433-11456. doi: 10.1021/acs.chemrev.8b00422 [11] XIE J, LU Y C. A retrospective on lithium-ion batteries[J]. Nature Communications, 2020, 11(1): 2499. doi: 10.1038/s41467-020-16259-9 [12] LI Q, LIU G, CHENG H R, et al. Low-temperature electrolyte design for lithium-ion batteries: prospect and challenges[J]. Chemistry-a European Journal, 2021, 27(64): 15842-15865. doi: 10.1002/chem.202101407 [13] LIU D D, WEI Z Y, LIU L M, et al. Ultrafine SnO2 anchored in ordered mesoporous carbon framework for lithium storage with high capacity and rate capability[J]. Chemical Engineering Journal, 2021, 406: 126710. doi: 10.1016/j.cej.2020.126710 [14] LI Q Y, JIAO S H, LUO L L, et al. Wide-temperature electrolytes for lithium-ion batteries[J]. ACS Applied Materials & Interfaces, 2017, 9(22): 18826-18835. [15] SMART M C, LUCHT B L, DALAVI S, et al. The effect of additives upon the performance of MCMB/LiNixCo1–xO2Li-ion cells containing methyl butyrate-based wide operating temperature range electrolytes[J]. Journal of the Electrochemical Society, 2012, 159(6): A739-A751. doi: 10.1149/2.058206jes [16] YANG B W, ZHANG H, YU L, et al. Lithium difluorophosphate as an additive to improve the low temperature performance of LiNi0.5Co0.2Mn0.3O2/graphite cells[J]. Electrochimica Acta, 2016, 221: 107-114. doi: 10.1016/j.electacta.2016.10.037 [17] KAFLE J, HARRIS J, CHANG J, et al. Development of wide temperature electrolyte for graphite/LiNiMnCoO2 Li-ion cells: high throughput screening[J]. Journal of Power Sources, 2018, 392: 60-68. doi: 10.1016/j.jpowsour.2018.04.102 [18] DING M S, XU K, ZHANG S S, et al. Liquid/solid phase diagrams of binary carbonates for lithium Batteries Part II[J]. Journal of the Electrochemical Society, 2001, 148(4): A299. doi: 10.1149/1.1353568 [19] DING M S, XU K, JOW T R. Liquid-solid phase diagrams of binary carbonates for lithium batteries[J]. Journal of the Electrochemical Society, 2000, 147(5): 1688. doi: 10.1149/1.1393419 [20] SMART M C, RATNAKUMAR B V, WHITCANACK L D, et al. Improved low-temperature performance of lithium-ion cells with quaternary carbonate-based electrolytes[J]. Journal of Power Sources, 2003, 119: 349-358. [21] DONG X L, GUO Z W, GUO Z Y, et al. Organic batteries operated at −70 ℃[J]. Joule, 2018, 2(5): 902-913. doi: 10.1016/j.joule.2018.01.017 [22] ZHENG H, XIANG H F, JIANG F Y, et al. Lithium difluorophosphate-based dual-salt low concentration electrolytes for lithium metal batteries[J]. Advanced Energy Materials, 2020, 10(30): 2001440. doi: 10.1002/aenm.202001440 [23] KIM K M, LY N V, WON J H, et al. Improvement of lithium-ion battery performance at low temperature by adopting polydimethylsiloxane-based electrolyte additives[J]. Electrochimica Acta, 2014, 136: 182-188. doi: 10.1016/j.electacta.2014.05.054 [24] ZHAO D N, WANG J, WANG P, et al. Regulating the composition distribution of layered SEI film on Li-ion battery anode by LiDFBOP[J]. Electrochimica Acta, 2020, 337: 135745. doi: 10.1016/j.electacta.2020.135745 [25] SHI J L, EHTESHAMI N, MA J L, et al. Improving the graphite/electrolyte interface in lithium-ion battery for fast charging and low temperature operation: fluorosulfonyl isocyanate as electrolyte additive[J]. Journal of Power Sources, 2019, 429: 67-74. doi: 10.1016/j.jpowsour.2019.04.113 [26] LEI Q F, YANG T X, ZHAO X Y, et al. Lithium difluorophosphate as a multi-functional electrolyte additive for 4.4 V LiNi0.5Co0.2Mn0.3O2/graphite lithium ion batteries[J]. Journal of Electroanalytical Chemistry, 2019, 846: 113141. doi: 10.1016/j.jelechem.2019.05.023 [27] ZHANG S S, XU K, JOW T R. EIS study on the formation of solid electrolyte interface in Li-ion battery[J]. Electrochimica Acta, 2006, 51(8-9): 1636-1640. doi: 10.1016/j.electacta.2005.02.137 [28] ZHANG S S. A review on electrolyte additives for lithium-ion batteries[J]. Journal of Power Sources, 2006, 162(2): 1379-1394. doi: 10.1016/j.jpowsour.2006.07.074 [29] GUO R D, CHE Y X, LAN G Y, et al. Tailoring low-temperature performance of a lithium-ion battery via rational designing interphase on an anode[J]. ACS Applied Materials & Interfaces, 2019, 11(41): 38285-38293. [30] SONG G, YI Z L, SU F Y, et al. New insights into the mechanism of LiDFBOP for improving the low-temperature performance via the rational design of an interphase on a graphite anode[J]. ACS Applied Materials & Interfaces, 2021, 13(33): 40042-40052. [31] WU B R, REN Y H, MU D B, et al. Lithium insertion/desertion properties of LiFePO4 cathode in a low temperature electrolyte modified with sodium chloride additive[J]. Solid State Ionics, 2014, 260: 8-14. doi: 10.1016/j.ssi.2014.03.006 [32] ZHAO D N, SONG S N, YE X S, et al. New insight into the mechanism of LiPO2F2 on the interface of high-voltage cathode LiNi0.5Mn1.5O4 with truncated octahedral structure[J]. Applied Surface Science, 2019, 491: 595-606. doi: 10.1016/j.apsusc.2019.06.146 [33] LIU Q Q, MA L, DU C Y, et al. Effects of the LiPO2F2 additive on unwanted lithium plating in lithium-ion cells[J]. Electrochimica Acta, 2018, 263: 237-248. doi: 10.1016/j.electacta.2018.01.058 [34] PHAM H Q, CHUNG G J, HAN J, et al. Interface stabilization via lithium bis(fluorosulfonyl)imide additive as a key for promoted performance of graphite‖LiCoO2 pouch cell under–20 ○C[J]. The Journal of Chemical Physics, 2020, 152(9): 094709. doi: 10.1063/1.5144280 [35] ZHANG X H, ZOU L F, XU Y B, et al. Advanced electrolytes for fast-charging high-voltage lithium-ion batteries in wide-temperature range[J]. Advanced Energy Materials, 2020, 10(22): 2000368. doi: 10.1002/aenm.202000368 [36] CHA J, HAN J G, HWANG J, et al. Mechanisms for electrochemical performance enhancement by the salt-type electrolyte additive, lithium difluoro(oxalato)borate, in high-voltage lithium-ion batteries[J]. Journal of Power Sources, 2017, 357: 97-106. doi: 10.1016/j.jpowsour.2017.04.094 [37] ZHANG Q L, PAN J, LU P, et al. Synergetic effects of inorganic components in solid electrolyte interphase on high cycle efficiency of lithium ion batteries[J]. Nano Letters, 2016, 16(3): 2011-2016. doi: 10.1021/acs.nanolett.5b05283 [38] GAO Y, ROJAS T, WANG K, et al. Low-temperature and high-rate-charging lithium metal batteries enabled by an electrochemically active monolayer-regulated interface[J]. Nature Energy, 2020, 5: 534-542. doi: 10.1038/s41560-020-0640-7 [39] ZHENG X Z, FANG G H, PAN Y, et al. Synergistic effect of fluoroethylene carbonate and lithium difluorophosphate on electrochemical performance of SiC-based lithium-ion battery[J]. Journal of Power Sources, 2019, 439: 227081. doi: 10.1016/j.jpowsour.2019.227081 [40] YAO Y X, CHEN X, YAN C, et al. Regulating interfacial chemistry in lithium-ion batteries by a weakly solvating electrolyte[J]. Angewandte Chemie, 2021, 133(8): 4136-4143. doi: 10.1002/ange.202011482 [41] MA T, NI Y X, WANG Q R, et al. Optimize lithium deposition at low temperature by weakly solvating power solvent[J]. Angewandte Chemie, 2022, 134(39): e202207927. doi: 10.1002/ange.202207927 [42] YANG Y, FANG Z, YIN Y, et al. Synergy of weakly-solvated electrolyte and optimized interphase enables graphite anode charge at low temperature[J]. Angewandte Chemie International Edition, 2022, 61(36): e202208345. doi: 10.1002/anie.202208345 [43] XU J, WANG X, YUAN N Y, et al. Graphite-based lithium ion battery with ultrafast charging and discharging and excellent low temperature performance[J]. Journal of Power Sources, 2019, 430: 74-79. doi: 10.1016/j.jpowsour.2019.05.024 [44] WANG Z X, SUN Z H, SHI Y, et al. Ion-dipole chemistry drives rapid evolution of Li ions solvation sheath in low-temperature Li batteries[J]. Advanced Energy Materials, 2021, 11(28): 2100935. doi: 10.1002/aenm.202100935 [45] JIANG L L, YAN C, YAO Y X, et al. Inhibiting solvent co-intercalation in a graphite anode by a localized high-concentration electrolyte in fast-charging batteries[J]. Angewandte Chemie International Edition, 2021, 60(7): 3402-3406. doi: 10.1002/anie.202009738 [46] LIN S S, HUA H M, LAI P B, et al. A multifunctional dual-salt localized high-concentration electrolyte for fast dynamic high-voltage lithium battery in wide temperature range[J]. Advanced Energy Materials, 2021, 11(36): 2101775. doi: 10.1002/aenm.202101775 [47] PENG Z, CAO X, GAO P Y, et al. High-power lithium metal batteries enabled by high-concentration acetonitrile-based electrolytes with vinylene carbonate additive[J]. Advanced Functional Materials, 2020, 30(24): 2001285. doi: 10.1002/adfm.202001285 [48] YAN C, JIANG L L, YAO Y X, et al. Nucleation and growth mechanism of anion-derived solid electrolyte interphase in rechargeable batteries[J]. Angewandte Chemie International Edition, 2021, 60(15): 8521-8525. doi: 10.1002/anie.202100494 [49] CHAE S, KWAK W J, HAN K S, et al. Rational design of electrolytes for long-term cycling of Si anodes over a wide temperature range[J]. ACS Energy Letters, 2021, 6(2): 387-394. doi: 10.1021/acsenergylett.0c02214 [50] DONG X L, LIN Y X, LI P L, et al. High-energy rechargeable metallic lithium battery at −70 ℃ enabled by a cosolvent electrolyte[J]. Angewandte Chemie International Edition, 2019, 58(17): 5623-5627. doi: 10.1002/anie.201900266 [51] JIA H P, ZOU L F, GAO P Y, et al. High-performance silicon anodes enabled by nonflammable localized high-concentration electrolytes[J]. Advanced Energy Materials, 2019, 9(31): 1900784. doi: 10.1002/aenm.201900784 [52] LIN S S, HUA H M, LI Z S, et al. Functional localized high-concentration ether-based electrolyte for stabilizing high-voltage lithium-metal battery[J]. ACS Applied Materials & Interfaces, 2020, 12(30): 33710-33718. [53] SONG G, YI Z L, SU F Y, et al. Boosting the low-temperature performance for Li-ion batteries in LiPF6-based local high-concentration electrolyte[J]. ACS Energy Letters, 2023, 8(3): 1336-1343. doi: 10.1021/acsenergylett.2c02903 [54] LI W, WAINWRIGHT D S, DAHN J R, et al. Rechargeable lithium batteries with aqueous electrolytes[J]. Science, 1994, 264(5162): 1115-1118. doi: 10.1126/science.264.5162.1115 [55] XU J J, JI X, ZHANG J X, et al. Aqueous electrolyte design for super-stable 2.5 V LiMn2O4 Li4Ti5O12 pouch cells[J]. Nature Energy, 2022, 7(2): 186-193. doi: 10.1038/s41560-021-00977-5 [56] NIAN Q S, TAO Z L. Aqueous batteries operated at ̶ 50 ℃[J]. Angewandte Chemie International Edition, 2019, 58(47): 16994-16999. doi: 10.1002/anie.201908913 [57] YUE J M, ZHANG J K, TONG Y X, et al. Aqueous interphase formed by CO2 brings electrolytes back to salt-in-water regime[J]. Nature Chemistry, 2021, 13(11): 1061-1069. doi: 10.1038/s41557-021-00787-y -

下载:

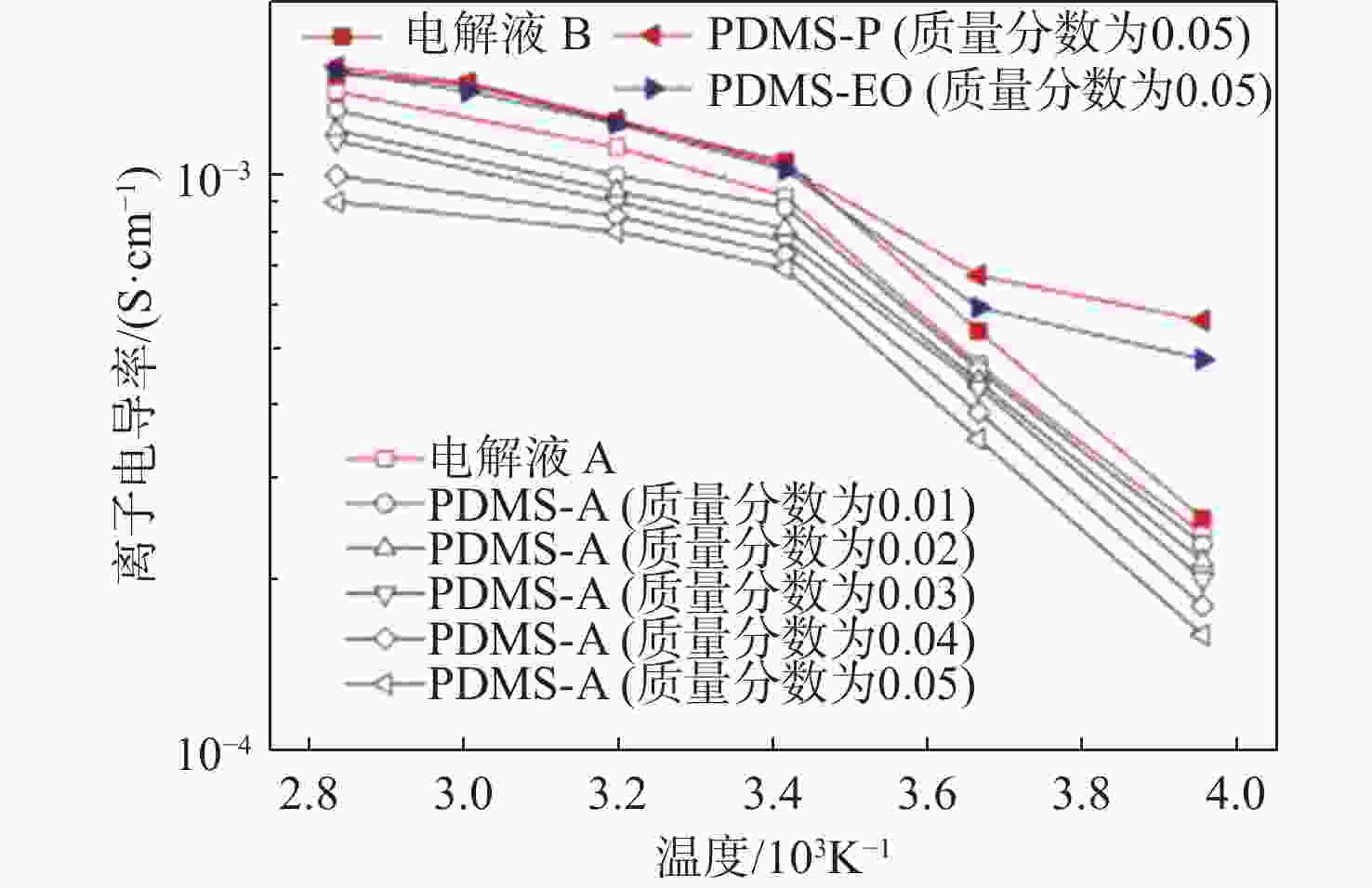

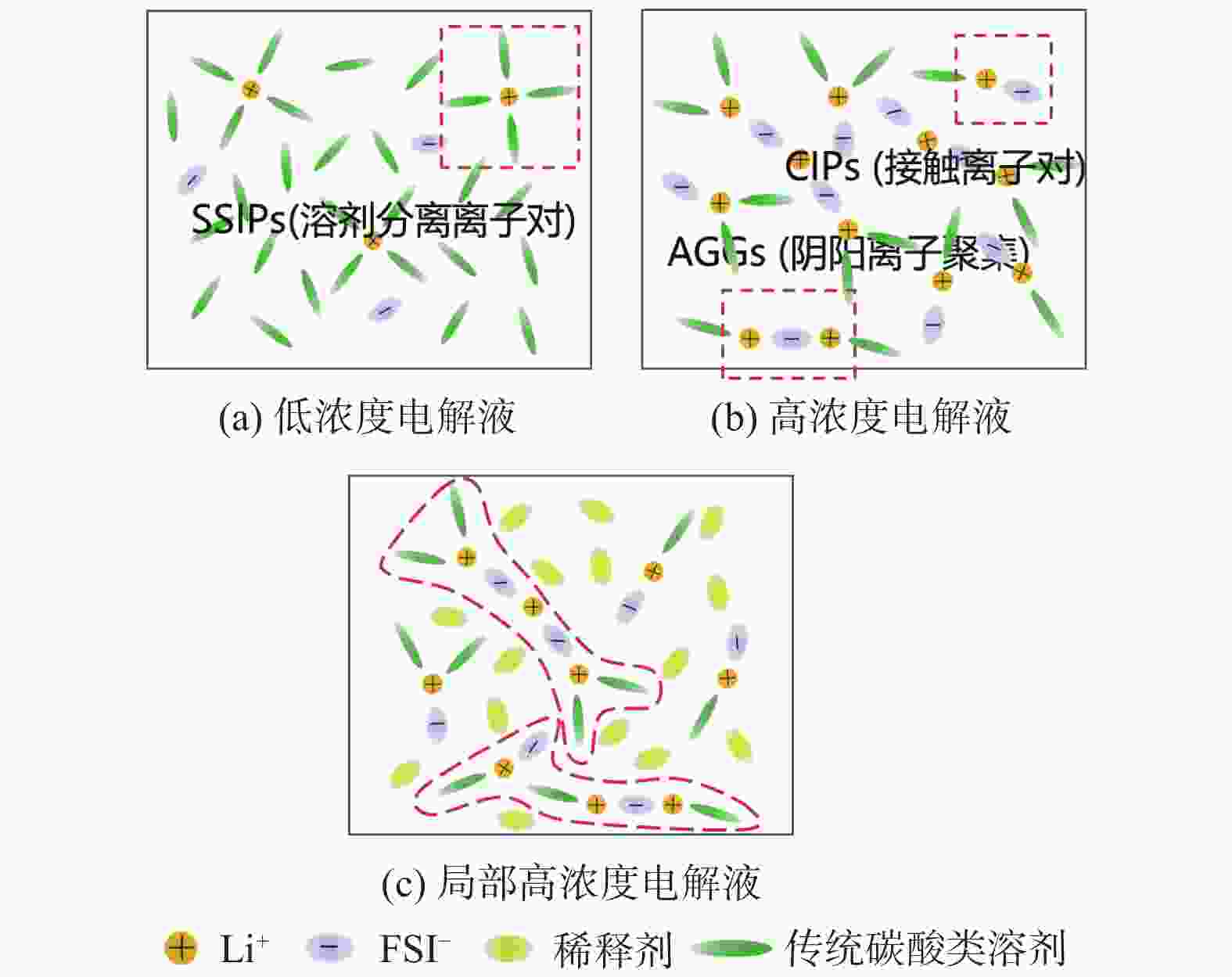

下载: