Progress in experimental research on flexible solar cells for near space application

-

摘要:

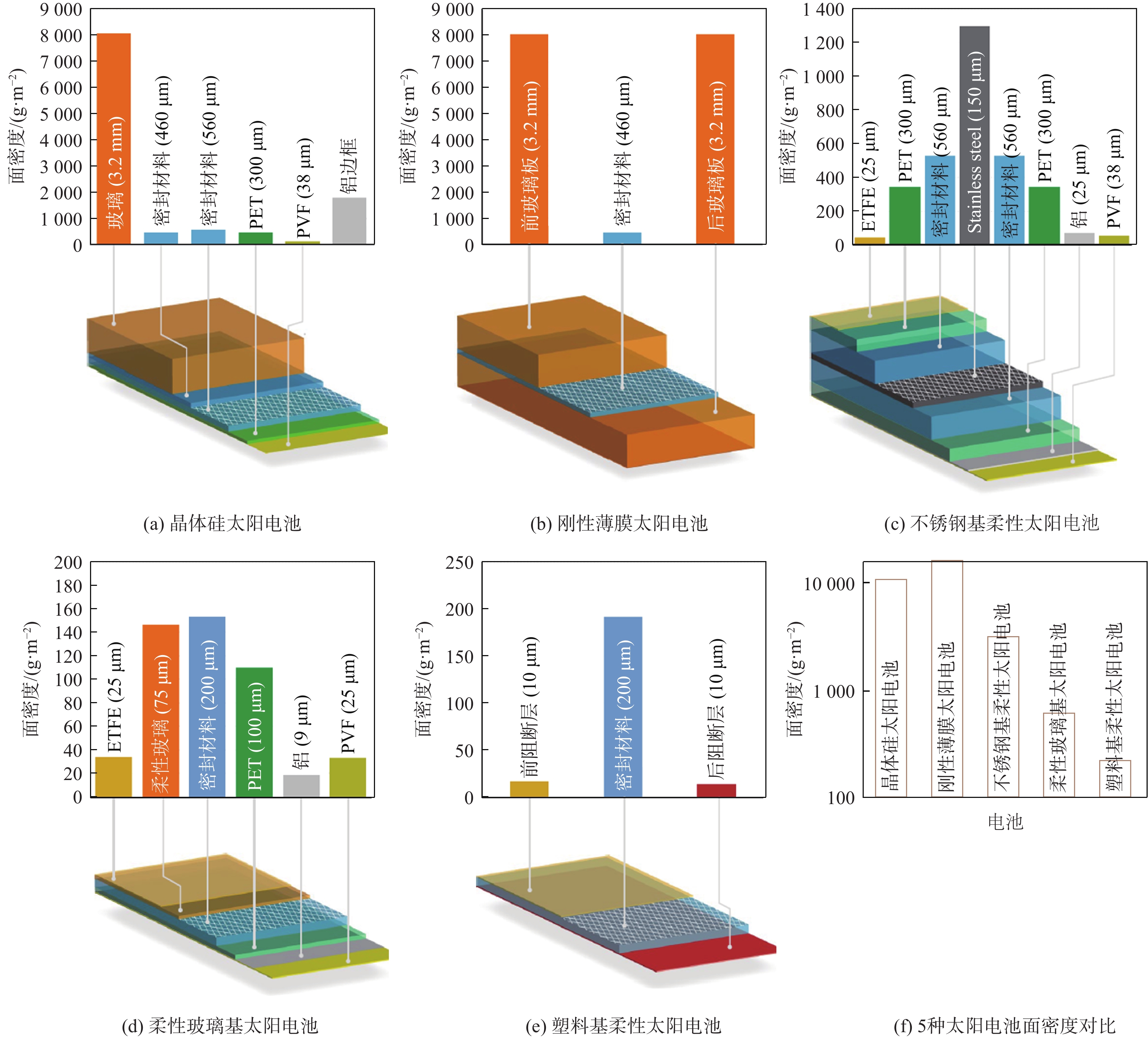

太阳电池是临近空间飞行平台理想的电源,柔性太阳电池因其较高的功质比得到越来越多的重视。分析不同种类太阳电池组件封装材料构成对电池面密度的影响,并计算柔性薄膜太阳电池组件不同转换效率对应的功质比;回顾柔性硅太阳电池、柔性铜铟镓硒太阳电池、柔性碲化镉太阳电池和柔性钙钛矿太阳电池研究进展;介绍每种柔性太阳电池所用基底材料、制备方法和效率制约因素等;介绍钙钛矿太阳电池在临近空间环境下的试验研究进展,指出柔性钙钛矿太阳电池下一步的研究方向。研究表明:由于柔性钙钛矿太阳电池具有较高的功质比,其是最具有临近空间应用潜力的柔性太阳电池。

Abstract:Solar cells are an ideal power supply solution for near-space flight platforms. Flexible solar cells, particularly, have attracted increasing attention due to their high specific power. In this paper, the influence of different types of solar cell module encapsulation materials on the areal density was analyzed first, and the specific power of flexible thin-film solar modules at different conversion efficiencies was calculated. The paper then reviewed the research advances in flexible solar cells, including flexible silicon, flexible copper indium gallium selenium, flexible cadmium telluride, and flexible perovskite solar cells. The substrate materials, fabrication methods, and efficiency constraints of each flexible solar cell were introduced in detail. In addition, the paper presented the research progress on perovskite solar cells in near-space environments and pointed out future research directions for flexible perovskite solar cells.Studies have shown that flexible perovskite solar cells are the most promising candidates for near-space applications due to their high power-to-weight ratio.

-

Key words:

- near space /

- flexible solar cell /

- power-to-weight ratio /

- thin-film solar cell /

- perovskite

-

表 1 柔性太阳电池组件效率及对应的功质比

Table 1. Flexible solar cell efficiency and power-to-weight ratio

柔性太阳电池

组件效率/%150 μm不锈钢基底

柔性组件功质比/(W·kg−1)塑料基底柔性

组件功质比/(W·kg−1)15 47 682 18 56 818 20 63 909 22 69 1000 -

[1] TU Y G, WU J, XU G N, et al. Perovskite solar cells for space applications: progress and challenges[J]. Advanced Materials, 2021, 33(21): 2006545. doi: 10.1002/adma.202006545 [2] GAO F L, HUA Z Z, TAO L R, et al. Impact of spectral solar irradiance variations on the energy balance of the earth[J]. Chinese Journal of Space Science, 2014, 34(4): 434. doi: 10.11728/cjss2014.04.434 [3] CHEN F G, CHEN G M, LIU K H. Analysis of near space environment and its effect[J]. Equipment Environmental Engineering, 2013, 10(4): 71-75. [4] YANG J M, BAO Q Y, SHEN L, et al. Potential applications for perovskite solar cells in space[J]. Nano Energy, 2020, 76: 105019. doi: 10.1016/j.nanoen.2020.105019 [5] REESE M O, GLYNN S, KEMPE M D, et al. Increasing markets and decreasing package weight for high-specific-power photovoltaics[J]. Nature Energy, 2018, 3(11): 1002-1012. doi: 10.1038/s41560-018-0258-1 [6] KALTENBRUNNER M, ADAM G, GŁOWACKI E D, et al. Flexible high power-per-weight perovskite solar cells with chromium oxide-metal contacts for improved stability in air[J]. Nature Materials, 2015, 14(10): 1032-1039. doi: 10.1038/nmat4388 [7] WANG H, CAO Y X, FENG J S, et al. Research on the development of flexible solar cells[J]. Chinese Journal of Engineering Science, 2018, 20(3): 66-73. doi: 10.15302/J-SSCAE-2018.03.010 [8] LEE T D, EBONG A U. A review of thin film solar cell technologies and challenges[J]. Renewable and Sustainable Energy Reviews, 2017, 70: 1286-1297. doi: 10.1016/j.rser.2016.12.028 [9] CARLSON D E, WRONSKI C R. Amorphous silicon solar cell[J]. Applied Physics Letters, 1976, 28(11): 671-673. doi: 10.1063/1.88617 [10] SAI H, MATSUI T, KOIDA T, et al. Triple-junction thin-film silicon solar cell fabricated on periodically textured substrate with a stabilized efficiency of 13.6%[J]. Applied Physics Letters, 2015, 106(21): 213902. doi: 10.1063/1.4921794 [11] YAN B J, YUE G Z, SIVEC L, et al. Innovative dual function nc-SiOx: H layer leading to a >16% efficient multi-junction thin-film silicon solar cell[J]. Applied Physics Letters, 2011, 99(11): 113512. doi: 10.1063/1.3638068 [12] HAUG F J, SÖDERSTRÖM T, PYTHON M, et al. Development of micromorph tandem solar cells on flexible low-cost plastic substrates[J]. Solar Energy Materials and Solar Cells, 2009, 93(6): 884-887. [13] YAN B J, YANG J, GUHA S. Amorphous and nanocrystalline silicon thin film photovoltaic technology on flexible substrates[J]. Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films, 2012, 30(4): 1-10. [14] RAPINETT A. Zephyr: a high altitude long endurance unmanned air vehicle[D]. Guildford: University of Surrey, 2009: 16-19. [15] CHAPIN D M, FULLER C S, PEARSON G L. A new silicon p-n junction photocell for converting solar radiation into electrical power[J]. Journal of Applied Physics, 1954, 25(5): 676-677. doi: 10.1063/1.1721711 [16] LONGi. At 26.81%, LONGi sets a new world record efficiency for silicon solar cells[EB/OL]. (2022-11-19)[2022-11-22]. http://www.longi.com/en/news/propelling-the-transformation/. [17] AUGUSTO A, TYLER K, HERASIMENKA S Y, et al. Flexible modules using <70 μm thick silicon solar cells[J]. Energy Procedia, 2016, 92: 493-499. doi: 10.1016/j.egypro.2016.07.132 [18] GAUCHER A, CATTONI A, DUPUIS C, et al. Ultrathin epitaxial silicon solar cells with inverted nanopyramid arrays for efficient light trapping[J]. Nano Letters, 2016, 16(9): 5358-5364. doi: 10.1021/acs.nanolett.6b01240 [19] BRANHAM M S, HSU W C, YERCI S, et al. 15.7% efficient 10-μm-thick crystalline silicon solar cells using periodic nanostructures[J]. Advanced Materials, 2015, 27(13): 2182-2188. doi: 10.1002/adma.201405511 [20] XUE M Y, NAZIF K N, LYU Z, et al. Free-standing 2.7 μm thick ultrathin crystalline silicon solar cell with efficiency above 12.0%[J]. Nano Energy, 2020, 70: 104466. doi: 10.1016/j.nanoen.2020.104466 [21] LIU W Z, LIU Y J, YANG Z Q, et al. Flexible solar cells based on foldable silicon wafers with blunted edges[J]. Nature, 2023, 617: 717-723. doi: 10.1038/s41586-023-05921-z [22] 杜付明. 阳光动力2号——不耗一滴油完成全球飞行揭秘[EB/OL]. (2015-09-06)[2022-11-20]. http://www.sic.cas.cn/zt/kpwsx/kpwz/201509/t20150906_4420167.html.DU F M. Solar Impulse 2——Uncover the secrets of global flight without using a drop of fuel[EB/OL]. (2015-09-06)[2022-11-20]. http://www.sic.cas.cn/zt/kpwsx/kpwz/201509/t20150906_4420167.html(in Chinese). [23] KAZMERSKI L L, WHITE F R, MORGAN G K. Thin-film CuInSe2/CdS heterojunction solar cells[J]. Applied Physics Letters, 1976, 29(4): 268-270. doi: 10.1063/1.89041 [24] KAMADA R, YAGIOKA T, ADACHI S, et al. New world record Cu(In, Ga)(Se, S)2 thin film solar cell efficiency beyond 22%[C]//Proceedings of the IEEE 43rd Photovoltaic Specialists Conference. Piscataway: IEEE Press, 2016: 1287-1291. [25] GIFFORD G. Inside TSMC's 16.5% CIGS module world record[EB/OL]. (2015-03-12)[2022-11-22]. http://www.pv-magazine.com/2015/05/12/inside-tsmcs-16-5-cigs-module-world-record_100019430/. [26] CARRON R, NISHIWAKI S, FEURER T, et al. Advanced alkali treatments for high-efficiency Cu(In, Ga)Se2 solar cells on flexible substrates[J]. Advanced Energy Materials, 2019, 9(24): 1900408. doi: 10.1002/aenm.201900408 [27] REINHARD P, CHIRILĂ A, BLÖSCH P, et al. Review of progress toward 20% efficiency flexible CIGS solar cells and manufacturing issues of solar modules[J]. IEEE Journal of Photovoltaics, 2013, 3(1): 572-580. doi: 10.1109/JPHOTOV.2012.2226869 [28] LIU X X, ZHAO Y Q, GONG J B, et al. Technical development and application of flexible Cu(In, Ga)Se2 solar cells[J]. Vacuum and Cryogenics, 2020, 26(5): 377-384. [29] BONNET D, RABENHORST H. New results on the development of a thin-film p-CdTe-n-CdS heterojunction solar cell[C]//Proceedings of the Photovoltaic Specialists Conference. Silver Spring:[s.n.], 1972: 129-132. [30] First Solar. Series 6 plus datasheet[EB/OL]. (2022-11-09)[2022-11-23]. http://www.firstsolar.com/-/media/First-Solar/Technical-Documents/Series-6-Plus/Series-6-Plus-Datasheet---Global.ashx?la=en. [31] MAHABADUGE H P, RANCE W L, BURST J M, et al. High-efficiency, flexible CdTe solar cells on ultra-thin glass substrates[J]. Applied Physics Letters, 2015, 106(13): 133501. doi: 10.1063/1.4916634 [32] PERRENOUD J, SCHAFFNER B, BUECHELER S, et al. Fabrication of flexible CdTe solar modules with monolithic cell interconnection[J]. Solar Energy Materials and Solar Cells, 2011, 95: S8-S12. doi: 10.1016/j.solmat.2010.11.019 [33] KRANZ L, GRETENER C, PERRENOUD J, et al. Doping of polycrystalline CdTe for high-efficiency solar cells on flexible metal foil[J]. Nature Communications, 2013, 4: 2306. doi: 10.1038/ncomms3306 [34] KOJIMA A, TESHIMA K, SHIRAI Y, et al. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells[J]. Journal of the American Chemical Society, 2009, 131(17): 6050-6051. doi: 10.1021/ja809598r [35] NREL. Best research-cell efficiency chart[EB/OL]. (2022-11-26)[2023-02-23]. http://www.nrel.gov/pv/cell-efficiency.html. [36] LI M H, ZHOU J J, TAN L G, et al. Multifunctional succinate additive for flexible perovskite solar cells with more than 23% power-conversion efficiency[J]. The Innovation, 2022, 3(6): 100310. doi: 10.1016/j.xinn.2022.100310 [37] WU J, CHEN P, XU H, et al. Ultralight flexible perovskite solar cells[J]. Science China Materials, 2022, 65(9): 2319-2324. doi: 10.1007/s40843-022-2075-7 [38] GONG O Y, HAN G S, LEE S, et al. Van der waals force-assisted heat-transfer engineering for overcoming limited efficiency of flexible perovskite solar cells[J]. ACS Energy Letters, 2022, 7(9): 2893-2903. doi: 10.1021/acsenergylett.2c01391 [39] 吴绚. 20.2%, 麦耀华教授团队柔性钙钛矿光伏组件获独立第三方认证[EB/OL]. (2021-12-07)[2022-11-23]. http://inet.jnu.edu.cn/2021/1208/c7173a667459/page.htm.WU X. 20.2%, Professor Mai’s team of flexible perovskite photovoltaic modules has been certified by an independent third party[EB/OL]. (2021-12-07)[2022-11-23]. http://inet.jnu.edu.cn/2021/1208/c7173a667459/page.htm(in Chinese). [40] CARDINALETTI I, VANGERVEN T, NAGELS S, et al. Organic and perovskite solar cells for space applications[J]. Solar Energy Materials and Solar Cells, 2018, 182: 121-127. doi: 10.1016/j.solmat.2018.03.024 [41] TU Y G, XU G N, YANG X Y, et al. Mixed-cation perovskite solar cells in space[J]. Science China Physics, Mechanics & Astronomy, 2019, 62(7): 974221. [42] WANG H, JIANG X, CAO Y X, et al. The first record of diurnal performance evolution of perovskite solar cells in near space[J]. Advanced Energy Materials, 2023, 13(2): 2202643. doi: 10.1002/aenm.202202643 -

下载:

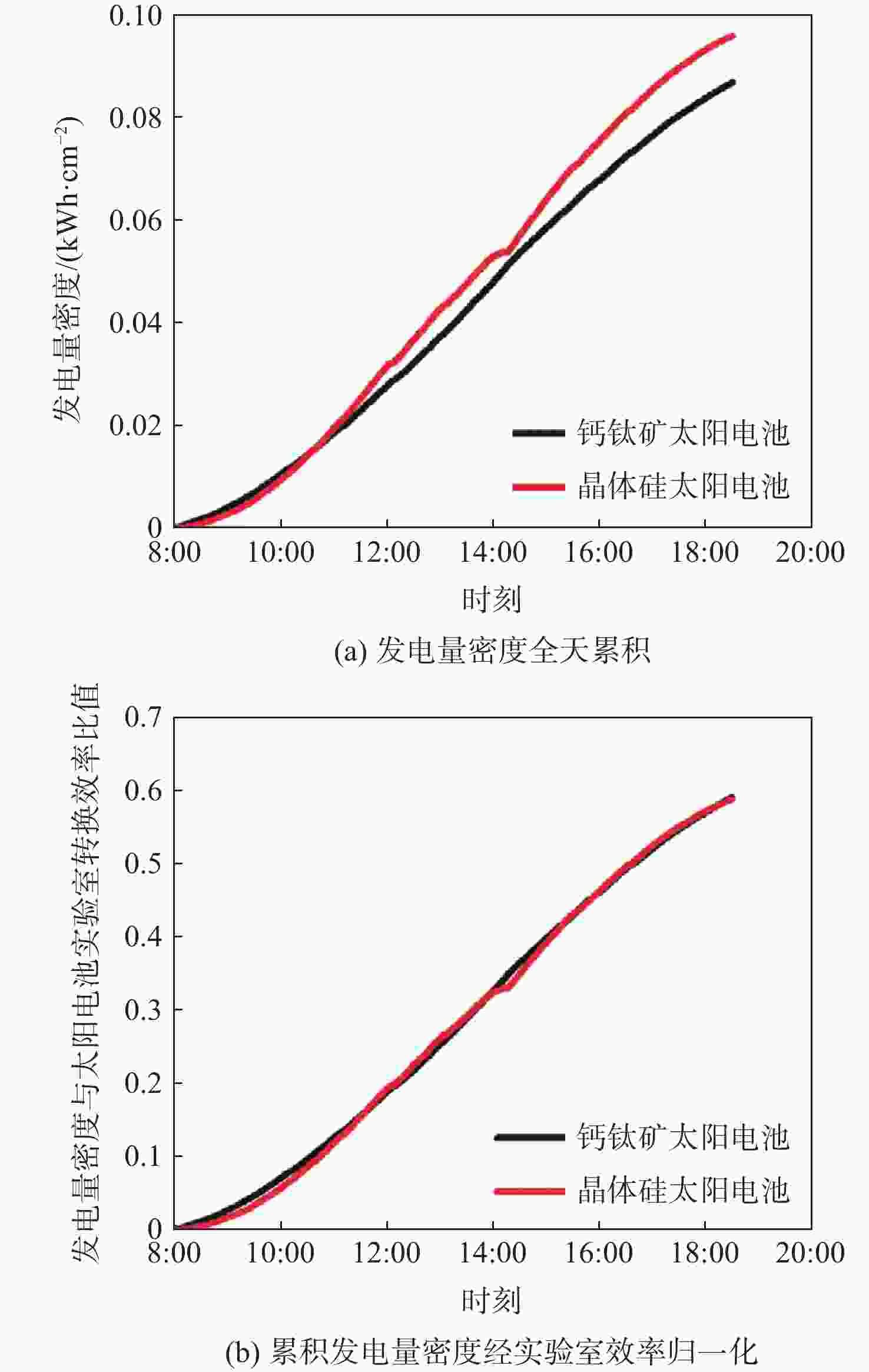

下载: