Precision improvement method for serial robot localization based on a new calibration and compensation strategy

-

摘要:

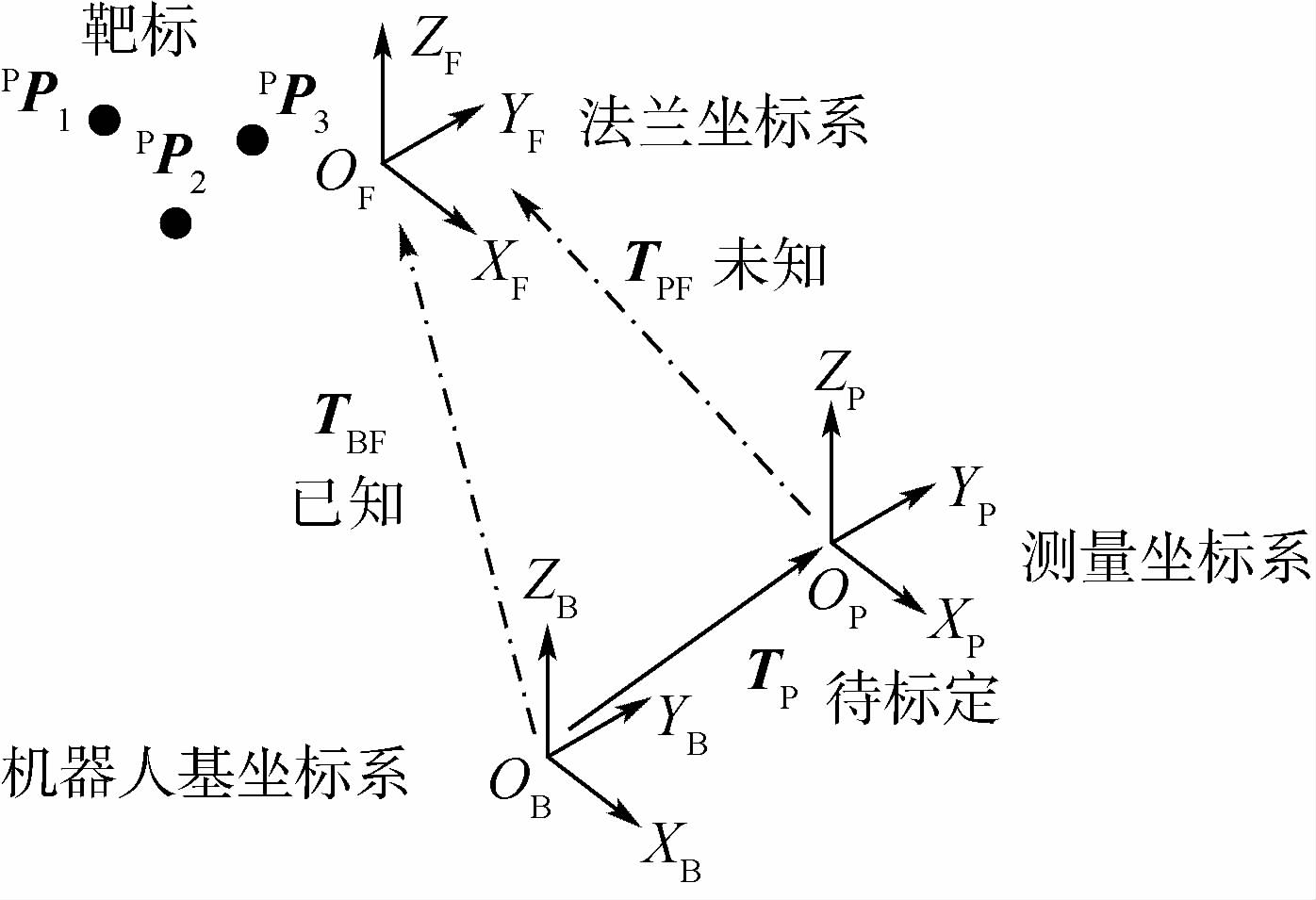

在使用串联机器人进行定位操作前,首先需要对机器人基坐标系与测量坐标系进行位姿关系的标定,针对具有隐藏机器人基坐标系以及机器人法兰坐标系的串联机构,本文提出一种等价变换思想并结合应用激光跟踪仪测得机器人末端靶标点的坐标数据建立标定矩阵方程,应用罗德里格矩阵变换将标定方程转化为三元二次矩阵方程形式,采用最小二乘法和牛顿迭代法求出数值解进而完成机器人基坐标系与测量坐标系标定的方法。然后应用这种方法进行标定试验得到了20组标定结果,通过比较标定结果偏差进而验证了这种方法的正确性。最后,本文验证了应用这种标定方法的标定结果并结合一种新的位姿补偿算法后,能极大地提高机器人末端的定位精度。

Abstract:Before the localization operation, the serial robot position relationship between base coordinate system and measurement coordinate system needs to be demarcated. For the hidden robot base and flange coordinate systems of serial mechanism, a kind of equivalent transformation method is presented in this paper, which is combined with the application of the target-points coordinate measurement data at the end of the robot using laser tracker to establish the calibration matrix equation. Calibration equation can be transformed into the ternary quadratic matrix equation form by Rodrigo matrix. Then the matrix equation between the robot base and measurement coordinate systems can be solved by using least square method and Newton iteration method. This method is verified by calibration test and 20 groups of calibration results are obtained. The calibration results combined with a position compensation algorithm can greatly improve the localization precision of robot.

-

Key words:

- robot /

- calibration /

- equivalent transformation method /

- compensation /

- localization precision

-

表 1 标定试验记录

Table 1. Records of calibration experiment

序号 1 2 3 4 5 6 X/mm 787.08 1 034.80 781.15 920.70 845.21 1 260.31 Y/mm 652.11 421.65 789.07 716.23 624.32 779.90 Z/mm 1 397.13 1 510.33 1 421.27 1 300.67 1 336.91 1 256.55 A/(°) -17.88 3.59 15.65 34.18 0.52 26.86 B/(°) -34.95 -14.42 13.12 14.70 26.71 50.43 C/(°) -131.82 -108.07 -77.79 -48.75 -122.20 -80.52 靶标点PP1/mm -1 451.694 1 -1 532.075 4 -1 389.275 6 -1 388.278 1 -1 465.091 5 -1 104.085 2 1 261.126 1 939.940 5 1 342.042 8 1 159.200 2 1 207.296 0 920.818 0 870.637 0 1 016.827 0 975.633 1 864.795 4 882.391 6 836.600 1 靶标点PP2/mm -1 481.243 6 -1 511.547 8 -1 356.844 6 -1 341.088 7 -1 492.635 2 -1 124.393 0 1 176.577 6 874.397 1 1 337.026 3 1 197.063 4 1 173.368 3 946.855 1 849.137 2 955.521 8 889.580 0 795.399 4 801.334 9 750.644 5 靶标点PP3/mm -1 429.139 9 -1 466.628 8 -1 306.996 3 -1 288.543 3 -1 413.111 0 -1 046.697 3 1 170.211 8 853.476 0 1 275.929 2 1 125.866 1 1 127.190 6 891.396 3 928.905 5 1 037.245 2 943.469 3 831.433 4 827.094 3 747.072 6 表 2 标定试验结果

Table 2. Results of calibration experiment

参数 Xr/mm Yr/mm Zr/mm Ar/(°) Br/(°) Cr/(°) 数值 2 614.63 1 173.67 490.06 55.31 -0.08 -0.21 表 3 通用补偿算法补偿实验靶标数据记录

Table 3. Target data records in compensation experimentwith universal compensation algorithmmm

mm 靶标序号 初始靶标 目标靶标 补偿前 补偿后 靶标点1 -1 408.80 -1 455.28 -1 455.39 -1 455.30 1 398.80 1 263.11 1 263.22 1 263.21 1 027.63 848.95 849.21 848.94 靶标点2 -1 416.39 -1 463.87 -1 463.99 -1 463.87 1 347.08 1 211.64 1 211.75 1 211.74 1 081.34 902.76 903.00 902.74 靶标点 -1 416.51 -1 450.18 -1 450.29 -1 450.18 1 400.22 1 262.90 1 263.00 1 263.00 1 140.48 961.97 962.22 961.95 表 4 通用补偿算法补偿前后靶标误差值

Table 4. Target error values before and afteruniversal compensation algorithmmm

mm 过程 靶标点1 靶标点2 靶标点3 补偿前 0.30 0.29 0.29 补偿后 0.10 0.10 0.10 表 5 新补偿算法补偿实验靶标数据记录1

Table 5. Target data record 1 in compensation experiment with the new compensation algorithmmm

mm 靶标序号 初始靶标 目标靶标 补偿前 补偿后 靶标点1 -1 408.82 -1 455.28 -1 455.34 -1 455.30 1 398.83 1 263.11 1 263.31 1 263.13 1 027.55 848.95 849.28 848.95 靶标点2 -1 416.41 -1 463.87 -1 463.94 -1 463.88 1 347.13 1 211.64 1 211.85 1 211.66 1 081.25 902.76 903.07 902.75 靶标点3 -1 416.52 -1 450.18 -1 450.25 -1 450.18 1 400.27 1 262.90 1 263.10 1 262.91 1 140.39 961.97 962.29 961.97 表 6 新补偿算法补偿前后靶标误差值

Table 6. Target error values before and after the new compensation algorithmmm

mm 过程 靶标点1 靶标点2 靶标点3 补偿前 0.39 0.38 0.39 补偿后 0.03 0.02 0.02 表 7 新补偿算法补偿实验靶标数据记录2

Table 7. Target error values before and after the new compensation algorithmmm

mm 靶标序号 初始靶标 目标靶标 补偿前 补偿后 靶标点1 -1 630.62 -1 470.65 -1 470.99 -1 470.67 631.62 385.45 385.36 385.43 888.57 875.46 876.05 875.47 靶标点2 -1 632.82 -1 458.37 -1 458.74 -1 458.38 681.02 434.08 433.99 434.06 940.35 926.55 927.13 926.57 靶标点3 -1 648.09 -1 473.47 -1 473.83 -1 473.49 611.25 364.67 364.57 364.65 947.85 937.06 937.64 937.08 表 8 补偿前后靶标误差值

Table 8. Target error values before and after compensation

mm 过程 靶标点1 靶标点2 靶标点3 补偿前 0.69 0.69 0.69 补偿后 0.03 0.03 0.03 -

[1] 王伟,刘立冬,王刚,等.基于四元数表示法的机器人基坐标系标定方法[J].北京亚洲成人在线一二三四五六区学报,2015,41(3):411-417.WANG W,LIU L D,WANG G,et al. Calibration method of robot base frame by quaternion form[J].Journal of Beijing University of Aeronautics and Astronautics,2015,41(3):411-417(in Chinese). [2] 宋月娥,吴林,张连新,等.弧焊机器人离线编程系统标定模块的开发[J].机器人,2001,23(7):695-697.SONG Y E,WU L,ZHANG L X,et al.Calibration module development of arc welding robot off-line programming system[J].Robot,2001,23(7):695-697(in Chinese). [3] 齐飞,平雪良,刘洁,等.关于工业机器人标定方法的研究[J].机床与液压,2015,43(21):32-36. http://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201521009.htmQI F,PING X L,LIU J,et al.Research of calibration method on industrial robot[J].Machine Tool & Hydraulics,2015,43(21):32-36(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JCYY201521009.htm [4] 张博,魏振忠,张广军.机器人坐标系与激光跟踪仪坐标系的快速转换方法[J].仪器仪表学报,2010,31(9):1986-1990. http://www.cnki.com.cn/Article/CJFDTOTAL-YQXB201009010.htmZHANG B,WEI Z Z,ZHANG G J.Rapid coordinate transformation between a robot and a laser tracker[J].Chinese Journal of Scientific Instrument,2010,31(9):1986-1990(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-YQXB201009010.htm [5] GAN Z,ROSSANO G,LI X,et al.Method for calibrating and programming of a robot application:US,Patent 6,822,412[P].2004-11-23. [6] GU X,FENG C.A calibration procedure for a system of two coordinated manipulators[J].International Journal of Robotics and Automation,1995,10(4):152-158. [7] 任永杰,邾继贵,杨学友,等.利用激光跟踪仪对机器人进行标定的方法[J].机械工程学报,2007,43(9):195-199. doi: 10.3901/JME.2007.09.195REN Y J,ZHU J G,YANG X Y,et al.Method of robot calibration based on laser tracker[J].Chinese Journal of Mechanical Engineering,2007,43(9):195-199(in Chinese). doi: 10.3901/JME.2007.09.195 [8] NUBIOLA A,BONEV I A.Absolute calibration of an ABB IRB 1600 robot using a laser tracker[J].Robotics and Computer Integrated Manufacturing,2013,29(1):236-245. doi: 10.1016/j.rcim.2012.06.004 [9] 黄晓辰,张明路,张小俊,等.机器人坐标系建立的改进DH法[J].农业机械学报,2014,45(10):313-319. http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201410049.htmHUANG X C,ZHANG M L,ZHANG X J,et al.Improved DH method to build robot coordinate system[J].Transactions of the Chinese Society for Agricultural Machinery,2014,45(10):313-319(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-NYJX201410049.htm [10] 戚祯祥,叶超强,吴建华,等.基于MDH模型的工业机器人标定算法与实验研究[J].制造业自动化,2015,37(2):15-18. http://www.cnki.com.cn/Article/CJFDTOTAL-JXGY201504006.htmQI Z X,YE C Q,WU J H,et al.Research on the algorithm and experiment of robot calibration based on MDH model[J].Manufacturing Automation,2015,37(2):15-18(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXGY201504006.htm [11] 周爱国,周飞,吕刚,等.关节臂式坐标测量机的运动学与工作空间分析[J].机械传动,2015,39(1):48-51. http://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201501014.htmZHOU A G,ZHOU F,LV G,et al.Kinematics and workspace analysis for articulated arm coordinate measuring machine[J].Journal of Mechanical Transmission,2015,39(1):48-51(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201501014.htm [12] 李新友, 陈五一.基于奇异值分解的刚体位姿误差检测方法[J].计算机集成制造系统,2011,17(9):1981-1987. http://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201109015.htmLI X Y,CHEN W Y.Detection of pose errors for a rigid body based on singular value decomposition method[J].Computer Integrated Manufacturing Systems,2011,17(9):1981-1987(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201109015.htm [13] 黄鹏, 王青,丽江熊,等.激光跟踪仪三维坐标转换综合优化方法[J].计算机集成制造系统,2015,21(11):2912-2920. http://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201511011.htmHUANG P, WANG Q,LI J X,et al.Comprehensive optimization for three-dimensional coordinate transformation of laser tracker[J].Computer Integrated Manufacturing Systems,2015,21(11):2912-2920(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-JSJJ201511011.htm [14] CAYLEY A.On the motion of rotation of a solid body[J].Cambridge Mathematic Journal,1843,3:224-232. [15] RODRIGUES O. Des lois géométriques qui régissent les déplacements d'un système solide dans l'espace,et de la variation de s coordonnées provenant de ses déplacements consideérés indépendamment des causes qui peuvent les produire[J].Journal des Mathématiques Pures et Appliquées,1840,5:380-440. [16] 陶武勇, 鲁铁定,吴飞,等.罗德里格矩阵坐标变换模型的结构总体最小二乘估计[J].工程勘察,2015(4):56-60. http://www.cnki.com.cn/Article/CJFDTOTAL-GCKC201504011.htmTAO W Y,LU T D,WU F,et al.Algorithm of structure total least squares in coordinate transformation based on Lodrigues matrix[J].Geotechnical Investigation & Surveying,2015(4):56-60(in Chinese). http://www.cnki.com.cn/Article/CJFDTOTAL-GCKC201504011.htm -

下载:

下载: